Product Description

w

Product Parameters

PLE series spur gear planetary gear motorPLF series spur gear planetary gear motor

Parameters

PLE planetary gearbox for servo motor

|

Model |

PLE /PLF SERIES |

|

Model |

PLE /PLF 60, 80, 90, 120, 160 |

|

4 optional sizes |

60mm, 90mm, 120mm, 160mm |

|

Rated Torque |

8.5N.m-680N.m |

|

Gear Ratio One-stage |

3, 4, 5, 7, 10 |

|

Gear Ratio Two-stage |

12, 16, 20, 25, 28, 35, 40, 50, 70 |

|

Gear Ratio Three-stage |

80, 100, 125, 140, 175, 200, 250, 280, 350 |

Note: There are many types of planetary gearboxes AS BELOW.

If you have any questions about the selection OR customization, please contact us first.

PRODUCT SPECIFICATIONS

PLE series spur gear planetary gear motor

Application

Product Description

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

Certifications

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Lubrication Practices for Maintaining Servo Gearbox Performance

Proper lubrication is essential for maintaining the performance and longevity of servo gearboxes:

1. High-Quality Lubricants: Selecting the right lubricant is crucial. High-quality lubricants with the appropriate viscosity and additives are chosen based on factors like load, speed, and operating conditions.

2. Lubricant Compatibility: Ensure that the chosen lubricant is compatible with the materials used in the gearbox construction, including seals, bearings, and gears.

3. Regular Lubrication Checks: Regularly inspect the lubricant level and condition. Monitor for signs of contamination, degradation, or overheating.

4. Proper Lubricant Amount: Avoid overfilling or underfilling the gearbox. Follow manufacturer guidelines for the correct lubricant amount to ensure optimal performance.

5. Scheduled Lubrication Intervals: Establish a maintenance schedule for lubricant replacement based on operating hours, usage intensity, and environmental conditions.

6. Lubricant Contamination Prevention: Keep the gearbox environment clean and free from contaminants like dust, dirt, and moisture to prevent lubricant contamination.

7. Lubricant Temperature: Monitor and control the operating temperature of the gearbox to prevent lubricant breakdown and ensure proper viscosity.

8. Re-Greasing: In some cases, re-greasing may be necessary due to lubricant aging or displacement. Follow manufacturer recommendations for re-greasing intervals.

9. Seal Inspection: Check the seals regularly for wear and damage. Damaged seals can lead to lubricant leakage and contamination.

10. Expert Consultation: If unsure about lubricant selection or maintenance procedures, consult with experts or follow manufacturer recommendations.

Proper lubrication practices play a critical role in minimizing friction, reducing wear, and ensuring the efficient operation of servo gearboxes in motion control systems.

Contribution of Servo Gearboxes to Energy Efficiency in Automated Systems

Servo gearboxes play a crucial role in enhancing energy efficiency in various automated systems by addressing several key aspects:

1. Precise Control: Servo gearboxes enable precise and accurate control over motion, allowing automated systems to perform tasks with minimal wastage of energy. Precise positioning reduces the need for unnecessary movements and adjustments.

2. Variable Speed Operation: Servo gearboxes offer the flexibility to operate at different speeds based on the application’s requirements. This capability ensures that the system uses only the necessary amount of energy for a given task, avoiding excessive power consumption.

3. Reduced Inertia: Servo gearboxes are designed to minimize inertia, which is the resistance to changes in motion. Lower inertia results in quicker response times and less energy required to accelerate or decelerate moving parts.

4. Regenerative Braking: Some servo systems are equipped with regenerative braking mechanisms. During deceleration or braking, energy generated is fed back into the system or stored for later use, reducing energy wastage.

5. Dynamic Load Management: Servo gearboxes can adapt to varying load conditions in real-time. They adjust torque and speed based on the load, optimizing energy usage and preventing overconsumption of power.

6. Reduced Heat Generation: Efficient servo gearboxes produce less heat during operation, leading to lower energy losses. This reduction in heat generation contributes to overall energy efficiency and extends the lifespan of components.

7. Smart Control Algorithms: Modern servo systems incorporate intelligent control algorithms that optimize the use of energy. These algorithms manage power distribution, minimize idle time, and synchronize movements for optimal efficiency.

8. Energy Recovery: In certain applications, servo gearboxes can capture and reuse energy that would otherwise be dissipated as heat. This energy recovery further contributes to the overall energy efficiency of the system.

9. Low Friction Designs: Servo gearboxes often incorporate low-friction components and efficient lubrication systems to minimize energy losses due to friction.

10. Matched Components: Properly matched servo gearbox and motor combinations ensure that the system operates at its peak efficiency point, minimizing energy consumption.

By incorporating these energy-saving features and capabilities, servo gearboxes enhance the energy efficiency of automated systems, making them more environmentally friendly and cost-effective over the long term.

Servo Gearbox: Function in Motion Control Systems

A servo gearbox is a specialized type of gearbox designed to work in conjunction with servo motors to achieve precise motion control in various applications. It functions as follows:

Motion Synchronization: A servo gearbox is used to synchronize the motion of a servo motor with the intended motion of a mechanical system. It ensures that the motor’s rotational output is accurately transmitted to the driven component.

Speed and Position Control: Servo gearboxes enable precise control over speed and position by converting the high-speed, low-torque output of a servo motor into a lower-speed, higher-torque output suitable for the specific application.

Reduction Ratio: The servo gearbox incorporates reduction stages to achieve the desired reduction ratio. This reduction allows the motor to provide higher torque while maintaining accurate speed control.

Backlash Minimization: High-precision servo gearboxes are designed to minimize backlash, which is the lost motion between input and output shafts. This is critical for accurate and responsive motion control.

High Efficiency: Servo gearboxes are designed for high efficiency to ensure that the majority of input power is effectively transferred to the output, reducing energy consumption.

Dynamic Response: Servo gearboxes enhance the dynamic response of motion control systems. They allow the servo motor to quickly start, stop, and change directions with minimal overshooting or oscillations.

Positioning Accuracy: By accurately converting the motor’s rotation into precise linear or angular movement, servo gearboxes ensure high positioning accuracy required in applications such as robotics, CNC machines, and automation systems.

Load Distribution: Servo gearboxes distribute the load evenly across gear teeth, enhancing the gearbox’s durability and minimizing wear.

Customization: Servo gearboxes are available in various sizes, reduction ratios, and configurations to suit different application requirements.

Overall, a servo gearbox is an integral component in motion control systems, allowing precise and efficient control over motion, speed, and position for a wide range of industrial applications.

editor by CX 2024-04-02

China supplier NEMA Low Backlash Precision Round Square Flange Spur Gear Planetary Transmission Gearbox for Stepper and Servo DC Motor planetary gearbox

Product Description

Product Description

The reducer is generally used for low-speed and high-torque transmission equipment. The motor, internal combustion engine or other high-speed running power is used to achieve the purpose of deceleration by meshing with the large gear on the output shaft through a gear with a small number of teeth on the input shaft of the reducer. The reducer will also have several pairs of gears with the same principle to achieve the ideal reduction effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.

| SPECIFICATIONS | STAGE | RATIO | RATED TORQUE (N.m) | ||

| Planetry Gearbox | L1 | 4 | 25 | ||

| 5 | 28 | ||||

| 7 | 20 | ||||

| 10 | 10 | ||||

| L2 | 16 | 30 | |||

| 20 | 30 | ||||

| 25 | 32 | ||||

| 28 | 30 | ||||

| 35 | 30 | ||||

| 40 | 25 | ||||

| 50 | 25 | ||||

| 70 | 20 | ||||

| Adapted motor | Stepper Motor/ Servo Motor | ||||

| Rated Input Speed (rpm) | 3000/min | ||||

| Max Input Speed (rpm) | 6000/min | ||||

| Backlash | L1 | ≤5-10 Arcmin | |||

| L2 | ≤10-15 Arcmin | ||||

| Fault stop torque(N.m) | 2 times of rated torque | ||||

| Efficiency | L1 | 96% | |||

| L2 | 94% | ||||

| Average life span | 20000h | ||||

| Operating temperature | -10°~+90° | ||||

| Nosie | ≤60 db | ||||

| Weight (kg) | L1 | 0.75-3.5 | |||

| L2 | 0.95-4.5 | ||||

| IP | 54 | ||||

| Installation method | Any installation method | ||||

Production Range

42 Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10,

L2: 12,16,20,25,28,35,40,50,70

Frame Dimension: 42mm Input Flange

Gear Arrangement: Planetary Straight Teeth

60 Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 60mm Input Flange

Gear Arrangement: Planetary Straight Teeth

90 Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 90mm Input Flange

Gear Arrangement: Planetary Straight Teeth

Powder Metal Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 42mm & 57mm

Gear Arrangement: Planetary Straight Teeth

Right Angle Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 60mm & 90mm

Gear Arrangement: Planetary Straight Teeth

Application Field

Automatic Arms

Assembly Line

3D-Printer

Medical -Equipment

CNC Machine

Tapping Machine

Other Automation Devices

Why Choose Us

ZheJiang High Precision Gear Transmission Co., Ltd

COMPANY

ZheJiang High Precision Gear Transmission Co., Ltd located in HangZhou city, ZheJiang Province, China. It is a leading company dedicated in precision transmission parts and system research, manufacture and sales, various series of products are manufactured in its 5000 square CHINAMFG workshop, the precision planetary gearbox and gear motor are developed especially for solar energy industry and have served many large-scale solar projects worldwidely.

The research team has more than 15 years experiences in this field, who can ensure a punctual and efficient service to meet customer’s specific needs. It has pasted the ISO9001 quality management system and CE, products have been exported to lots of countries with a wide range application in AGV, intelligent robot, logistic, industrial automation, solar energy, vessel, packaging and textile etc.Consistently, our goal is to promote the application of solar power industry in the world, and we believe it provides clean and sustainable energy for humanity to better protect our environment.

WORKSHOP

CERTIFICATIONS

FAQ

Q:Which areas are your products mainly used in?

A:At present, we have 2 main products: precision planetary gear reducer and solar geared motor. Most of the precision planetary reducers are used in automation fields, such as medical equipment, 3D printers, door openers, tapping machines, CNC lathes and a series of automation equipment. In addition, our solar geared motors are used in photovoltaic power generation projects, which are mainly combined with rotary drives to drive solar panels to track sunlight.

Q : How to choose the suitable planetary gearbox?

A :First of all, we need you to be able to provide relevant parameters. If you have a motor drawing, it will let us recommend a suitable gearbox for you faster. If not, we hope you can provide the following motor parameters: output speed, output torque, voltage, current, IP, noise, operating conditions, motor size and power, etc.

Q : What is the price ?

A : The main determining factor for the price of each product is the order volume. You can communicate with us and let us understand each other. I believe that our prices, product quality and our services can definitely make you satisfied.

Q : Do you provide customized service?

A : Yes, we provide customized services. You only need to put CHINAMFG your needs, and we will do our best to provide you with a plan, make plans, and try our best to meet your needs.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery, Laser Cutting Machine |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Double-Step |

| Samples: |

US$ 80/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Compatibility of Servo Gearbox with a Specific Motor

The compatibility between a servo gearbox and a specific motor depends on several key factors:

1. Mounting Configuration: The mounting interface of the servo gearbox and motor must be compatible. This includes the type of coupling, flange size, and bolt pattern. Proper alignment ensures efficient power transmission and minimizes mechanical stress.

2. Shaft Diameter and Keyway: The diameter and keyway of the motor shaft must match the input shaft of the servo gearbox. A precise fit prevents slippage and ensures accurate torque transmission.

3. Torque and Speed Ratings: The torque and speed requirements of the application should align with the torque and speed ratings of both the motor and gearbox. Oversizing or undersizing either component can lead to inefficient operation and premature wear.

4. Inertia Matching: Inertia matching between the motor and gearbox helps prevent resonance and oscillations in the system. An appropriate inertia match ensures smooth and precise motion control.

5. Backlash and Stiffness: The gearbox’s backlash (play in the gears) and stiffness characteristics should match the application’s requirements. Low backlash and high stiffness are crucial for accurate positioning tasks.

6. Efficiency and Heat Dissipation: The combined efficiency of the motor and gearbox affects the overall system efficiency. Inadequate efficiency can lead to energy losses and excessive heat generation.

7. Service Life and Maintenance: Compatibility also involves considering the expected service life and maintenance requirements. A well-matched motor-gearbox combination enhances the durability and reliability of the motion control system.

8. Control and Feedback: The control system’s capabilities, such as closed-loop control and feedback devices, play a role in determining compatibility. The motor and gearbox should provide the necessary interfaces for effective integration into the control system.

Manufacturers and engineers often provide guidelines and compatibility charts to assist in selecting the right servo gearbox for a specific motor. Considering these factors ensures optimal performance, efficiency, and longevity of the motion control system.

Contribution of Servo Gearboxes to Energy Efficiency in Automated Systems

Servo gearboxes play a crucial role in enhancing energy efficiency in various automated systems by addressing several key aspects:

1. Precise Control: Servo gearboxes enable precise and accurate control over motion, allowing automated systems to perform tasks with minimal wastage of energy. Precise positioning reduces the need for unnecessary movements and adjustments.

2. Variable Speed Operation: Servo gearboxes offer the flexibility to operate at different speeds based on the application’s requirements. This capability ensures that the system uses only the necessary amount of energy for a given task, avoiding excessive power consumption.

3. Reduced Inertia: Servo gearboxes are designed to minimize inertia, which is the resistance to changes in motion. Lower inertia results in quicker response times and less energy required to accelerate or decelerate moving parts.

4. Regenerative Braking: Some servo systems are equipped with regenerative braking mechanisms. During deceleration or braking, energy generated is fed back into the system or stored for later use, reducing energy wastage.

5. Dynamic Load Management: Servo gearboxes can adapt to varying load conditions in real-time. They adjust torque and speed based on the load, optimizing energy usage and preventing overconsumption of power.

6. Reduced Heat Generation: Efficient servo gearboxes produce less heat during operation, leading to lower energy losses. This reduction in heat generation contributes to overall energy efficiency and extends the lifespan of components.

7. Smart Control Algorithms: Modern servo systems incorporate intelligent control algorithms that optimize the use of energy. These algorithms manage power distribution, minimize idle time, and synchronize movements for optimal efficiency.

8. Energy Recovery: In certain applications, servo gearboxes can capture and reuse energy that would otherwise be dissipated as heat. This energy recovery further contributes to the overall energy efficiency of the system.

9. Low Friction Designs: Servo gearboxes often incorporate low-friction components and efficient lubrication systems to minimize energy losses due to friction.

10. Matched Components: Properly matched servo gearbox and motor combinations ensure that the system operates at its peak efficiency point, minimizing energy consumption.

By incorporating these energy-saving features and capabilities, servo gearboxes enhance the energy efficiency of automated systems, making them more environmentally friendly and cost-effective over the long term.

Servo Gearbox: Function in Motion Control Systems

A servo gearbox is a specialized type of gearbox designed to work in conjunction with servo motors to achieve precise motion control in various applications. It functions as follows:

Motion Synchronization: A servo gearbox is used to synchronize the motion of a servo motor with the intended motion of a mechanical system. It ensures that the motor’s rotational output is accurately transmitted to the driven component.

Speed and Position Control: Servo gearboxes enable precise control over speed and position by converting the high-speed, low-torque output of a servo motor into a lower-speed, higher-torque output suitable for the specific application.

Reduction Ratio: The servo gearbox incorporates reduction stages to achieve the desired reduction ratio. This reduction allows the motor to provide higher torque while maintaining accurate speed control.

Backlash Minimization: High-precision servo gearboxes are designed to minimize backlash, which is the lost motion between input and output shafts. This is critical for accurate and responsive motion control.

High Efficiency: Servo gearboxes are designed for high efficiency to ensure that the majority of input power is effectively transferred to the output, reducing energy consumption.

Dynamic Response: Servo gearboxes enhance the dynamic response of motion control systems. They allow the servo motor to quickly start, stop, and change directions with minimal overshooting or oscillations.

Positioning Accuracy: By accurately converting the motor’s rotation into precise linear or angular movement, servo gearboxes ensure high positioning accuracy required in applications such as robotics, CNC machines, and automation systems.

Load Distribution: Servo gearboxes distribute the load evenly across gear teeth, enhancing the gearbox’s durability and minimizing wear.

Customization: Servo gearboxes are available in various sizes, reduction ratios, and configurations to suit different application requirements.

Overall, a servo gearbox is an integral component in motion control systems, allowing precise and efficient control over motion, speed, and position for a wide range of industrial applications.

editor by CX 2024-01-05

China Best Sales China low price 57mm planetary reducer gearbox for nema23 stepper motor or nema 23 brushless dc motor near me shop

Applicable Industries: Automated industry

Gearing Arrangement: Planetary

Output Torque: 40NM

Input Speed: 0-3000rpm

Output Speed: 0-750rpm

Type:: PX80 Planetary gearbox

Ratio:: 4/5/6/10/16/20/24/30/36/64/96/144/216

Color:: Black

Noise:: noise (<65DB)

Material:: Aluminium Alloy or Cast Iron

Usages:: Industrial Machine

Warranty:: 1year

Packaging Details: Carton and wooden case

China low price 57mm planetary reducer gearbox for nema23 stepper motor or nema 23 brushless dc motor

Provide custom other spec reducer and deceleration ratio! DIY Tuya Remote Control Motorized Chain Motor Smart blinds shades device No matter the quantity as long as you can provide drawings we can make it! water cooling 6P SSS 5694 brushless inner rotor dc motor using for remote control model airplane

KeyWords

Planetary gearbox

Model

PX57

Ratio

1-stage:4/5/6/102-stage:16/20/24/30/36

3-stage:64/96/144/216

Color

Black/Silver or on customer request

Warranty

1 year

Packing

Carton and wooden case

Mass

1.4Kg

Get a discount

product assortment

Service

Customer service officer

Our customer service personnel are experienced product specialists who can answer your questions 7 days a week from

9 am to 5 pm.

Contact us now.

OEM / ODMOur professional staffs allow us to have the capability to design and manufacture a wide range of new items according to the buyer’s requirements. Our ability to provide buyers labels and design services for our clients make us an attractive choice.

Firm teamTimes Brilliant is committed to delivery quality products. We guarantee our products to be free from manufacture defects.

We offer one-month of return & Heavy duty Hook Type H419 crane lifting snatch pulley block exchange service, HAASBELTS Roller Top CZPT Modular Belt plastic Conveyor for Tire one-year of parts replacement and lifetime tech support

Factory Tour

Types of Gearboxes Used in Wind Turbines

Many manufacturers of wind turbines have chosen different solutions for the drive train of the turbines. Most prefer gearboxes because of their durability. These have several design features that make them well suited to shocks, stresses and wear. Regardless of the type of gearbox used, continuous maintenance and monitoring can extend the lifespan of these machines. Performing these tasks regularly can help detect and resolve any problems before they become serious. Here are some of the problems associated with gearboxes.

Coaxial helical gearbox

The R series helical inline gearbox is a high-quality speed reducer for heavy-duty industrial applications. These units are designed with increased power density in mind and are equipped with various cooling options. High-grade seals and lubricants help to increase efficiency and minimize thermal loading. They are ATEX-compliant. Their reversible modules are an excellent choice for high-speed applications, such as compressors, compressor blowers, and pumps.

The normal module set of helical gearbox is manufactured using the same tooth-cutting techniques as spur gears. This allows the production of higher-quality, more economical, and more compact helical gears. Although the performance of helical gears is lower than spur gears, they are durable and capable of transferring motion and power between two shafts. And because they are able to handle a much greater load, they are preferred for heavy-duty applications.

The main tooth form of a helical gearbox presents fixed velocity ratios, even if the center gap is not completely set. This requirement is sometimes referred to as the fundamental rule of gearing. A helical gearbox is similar to a set of paper spur gears, with the exception that the sections must stagger in opposite directions. There are two kinds of helical gears for parallel shafts: left-handed and right-handed.

The Industrial Gearbox market is segmented based on product type, application, and geography. The report analyzes the competitive scenario by segmenting the market by region, company, and type. Using this information, it estimates market size, revenue, and consumption. The report also features key information about COVID-19 and its impact on the overall industry. And it also provides a competitive landscape with industry-leading players.

Industrial gearboxes are integrated with devices and make automation processes more efficient and reliable. Increasing labor costs, shortage of skilled labor, and the ageing workforce are driving the demand for automation technologies. The industry requires newer and more advanced models and technologies to compete in the global market. You can use Coaxial helical gearbox in a variety of applications. Its benefits are endless. If you are looking for a reliable, high-performance industrial gearbox, CZPT can help you find it.

Worm reduction gearbox

As a general rule, larger center distance worm reduction gearboxes are more efficient than smaller ones. Worm gearboxes with 2.6-in. center distances start to lose efficiency as their ratios increase. Larger center distances tend to have higher efficiency than smaller ones. However, this difference may not always be enough to justify the higher investment. Worm gear reducers typically cost less than equivalent helical units.

The use of aluminum for worm reduction gearboxes is a popular choice for those involved in the manufacturing of Packaging Equipment. In addition to being lightweight, aluminum worm reduction gearboxes have high strength and rigidity. Manufacturers recommend this choice because of its high rigidity and durability. While purchasing aluminum worm reduction gearboxes, keep in mind that they are more expensive than steel versions. However, they have a longer lifespan and are highly resistant to wear.

The worm’s helix angle is larger than a helical gear, which allows a much higher gear ratio. In addition, the worm’s body is usually longer in the axial direction than helical gears. Worm reduction gears are often left-handed, and British or Indian standards are usually followed. The worm wheel is made of hardened alloy steel PB2-C, while the gearbox case is made of hardened alloy steel FG 220 or FG 250res.

The worms in a sacrificial system are relatively safe from wear. Instead, the softer wheel is the cause of most wear and tear. The oil analysis report for a sacrificial system shows low iron levels and high copper concentrations. However, if a worm reduction gearbox has a bad reputation, you should consider purchasing a new one. If the worm gears are in good condition, the gearbox is still a viable option for a new or replacement vehicle.

The advantages of a worm reduction gearbox are numerous. The worm gearbox is widely used in industrial settings, where it provides torque and speed reduction to move products. Worm gearboxes are also commonly used in automatic security gates, which will not run in reverse. Most security gates use two separate worm drives to keep the gate in the closed position. There are also many other uses for worm reducers. You can learn more about the benefits of worm gearboxes by reading below.

Stainless steel gearbox

Stainless steel gearboxes offer a number of advantages over standard gearboxes. They match the existing stainless motor design and cost 50 percent more on average. They have stainless output shafts and housings as well as corrosion resistant hardware and a food grade lubricant. Stainless steel gearboxes feature IP 65 sealing, Viton shaft seals at the input and output shafts, and a Buna o-ring between the housings. Stainless steel gearboxes also eliminate flat surfaces and allow for a cylindrical design.

Stainless steel gearboxes are more durable than traditional cast iron or epoxy-painted gearboxes. These gearboxes can withstand repeated washdown operations without damage. They also do not collect particles or bacteria. And because stainless steel does not corrode, stainless steel gearboxes can withstand harsh environments, such as oily or greasy environments. Because stainless steel gearboxes are corrosion-resistant, they require little maintenance. They are also easier to clean and maintain, resulting in fewer replacements and a longer life span for your gearbox.

Stainless steel gearboxes are a great choice for food and other industries that require high hygiene standards. In addition to its durability, stainless steel gearboxes are ideal for applications in environments that require high levels of humidity and water. They are also life-lubricated, and they can be supplied with food-grade oils or water. The CZPT Gears stainless gearbox is a versatile option for a variety of applications.

Stainless steel gearboxes offer superior corrosion protection and can withstand harsh environments. The stainless steel cover, housing, and external hardware ensure superior corrosion protection. If you have questions about the varying benefits of stainless steel gearboxes, contact a CZPT Gear sales representative to learn more about your options. And if you are not sure which type is right for your needs, contact a CZPT Gear sales representative to find the perfect solution for your business.

1 speed gearbox

Volkswagen Group Components manufactures the one speed gearbox. The gearbox has a high-performance electric drive motor that produces 310 Nm of torque over a wide speed range. Designed for maximum range, this gearbox uses a single gear for all driving situations. It is extremely quiet, too, and requires precision manufacturing. Volkswagen has also made it available in a reverse-gear configuration with power electronics. Volkswagen’s ID.3 EV’s e-drive motor is a perfect example of this.

The first part of the transmission corresponds to the even and odd gears, while the second part has the straighter gears. A single gear set can change between both modes. An intermediate gear set is also possible. A lastshelf gear can be formed by hydraulically betigte Lamellenkupplungen. Both types of gears can be exchanged between partial transmissions. The invention may furthermore include a transmission with the same gear ratios as the first part of the transmission.

Another variation of the one speed gearbox is the CVT. This type of gearbox has only one drive unit, which means it does not require a clutch or brake. Its power is derived from the torque generated by the Internal Combustion Engine at a particular speed. The engine cannot sustain such high torque levels above 5500 RPM, which will reduce the MPG. Also, raising the RPM will reduce the acceleration, and in severe cases may lead to an engine crash.

As the number of applications for a 1 speed gearbox increases, its design and functionality will continue to evolve. Bosch Rexroth has developed its eGFZ gearbox based on customer feedback. They are currently working on various pilot projects and hope to put it into production in the next few years. However, if you want to buy a 1 speed gearbox now, consider the benefits of a first-rate design.

in Samarkand Uzbekistan sales price shop near me near me shop factory supplier High Torque NEMA 16 1.8 Degree Mini Stepper Motor manufacturer best Cost Custom Cheap wholesaler

Ever-Electrical power Group CO., LTD. IS Professional IN Making ALL Types OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Speed REDUCERS, PARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Equipment REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Vehicle GEARBOXES, PTO Generate SHAFTS, Unique REDUCER & Related Equipment Factors AND OTHER Associated Merchandise, SPROCKETS, HYDRAULIC Technique, VACCUM PUMPS, FLUID COUPLING, Equipment RACKS, CHAINS, TIMING PULLEYS, UDL Speed VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Low BACKLASH WORM REDUCERS AND SO ON. The group is centered on generating all variety of normal roller chains and sprockets, gears & gearboxes, this sort of as conveyor chain & sprockets , stainless metal chain, agricultural chain and has not just offered its merchandise all in excess of china, but also sold much more than sixty five% merchandise to oversees, such as Europe, The us, South-east Asia, and it also has established up storage logistics in areas like Europe. We examine every piece of bearing by ourselves before supply. A. Specification of Substantial Torque NEMA sixteen one.eight Diploma Mini Stepper EPTT:

1. Stage: 2

2. Stage Angle: one.eight diploma

3. EPTT Torque: eight-24N.cm

4. EPTT Wire: 4/six

5. EPTT Length: twenty-40mm

six. EPTT Excess weight: one hundred-210g

seven. Shaft: Customized like D-minimize, spherical or with hole

Observe: The information sheet is only for reference, We can make the motor according to your necessity soon after Analysis

B. Organization Potential

HangEPTT EPTT EPTT Co. Ltd is a manufacturer and exporter of numerous of motors with more than 10 many years encounter.

Our product ranges incEPTT:

one) DC Brush motor: six-130mm diameter, .01-1000W output EPTT

2) DC Spur Gear EPTT: twelve-110mm diameter, .1-300W output EPTT

three) DC Planeary Gear EPTT: ten-82mm diameter, .1-100W output EPTT

4) Brushless DC EPTT: 28-110mm, 5-1500W output EPTT

5) Stepper EPTT: NEMA 08 to NEMA forty three, Can with EPTT and lead screw

six) Servo EPTT: 42mm to 130mm diameter, 50-4000w

seven) AC Gear EPTT: 49 to 100mm diameter, six-140 output EPTT

1. Manufacturing Line:

two. Tests EPTT:

three. Certificates:

four. Client Visits:

6. FAQ:

Q: What’s your primary items?

A:We presently produce Brushed Dc EPTTs, Brushed Dc EPTT EPTTs, Planetary Dc Gear EPTTs, Brushless Dc EPTTs, Stepper motors and Ac EPTTs and so forth. You can check out the technical specs for above motors on our website and you can e mail us to advocate necessary motors for each your specification way too.

Q:How to decide on a suited motor?

A:If you have motor pictures or drawings to show us, or you have comprehensive specs like voltage, speed, torque, motor dimensions, operating method of the motor, essential lifestyle time and sounds stage etc, please do not hesitate to permit us know, then we can advocate suitable motor for every your ask for accordingly.

Q: Do you have EPT services for your stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd motors?

A:Indeed, we can customise for every your ask for for the voltage, pace, torque and shaft measurement/condition. If you need to have additional wires/cables soldered on the terminal or need to have to include connectors, or capacitors or EMC we can make it way too.

Q:Do you have person design provider for motors?

A:Of course, we would like to design motors independently for our buyers, but it could require some mould charge and style demand.

Q:Can I have samples for testing very first?

A:Yes, undoubtedly you can. After confirmed the necessary motor specs, we will estimate and supply a proforma invoice for samples, when we get the payment, we will get a Move from our account office to commence samples appropriately.

Q:How do you make sure motor quality?

A:We have our very own inspection methods: for incoming supplies, we have signed sample and drawing to make sure experienced incoming materials for production procedure, we have tour inspection in the process and final inspection to make sure certified products ahead of transport.

Q:What is actually your lead time?

A:EPTTly sEPTTing, our normal stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd merchandise will want 25-30days, a bit EPTTer for EPT merchandise. But we are extremely fleXiHu (West Lake) Dis.ble on the direct time, it will depends on the particular orders

Q:What is actually your payment time period?

A:For all our new buyers, we will require 40% deposite, sixty% paid out prior to shipment.

Q:When will you reply following obtained my inquiries?

A:We will reaction in 24 hrs when get your inquires.

Q:How can I EPTT you to make certain my cash is secure?

A:We are certified by the 3rd get together SGS and we have exported to over eighty five international locations up to June.2017. You can examine our reputation with our present clients in your nation (if our consumers do not thoughts), or you can orEPTTvia alibaba to get trade assurance from alibaba to make positive your cash is secure.

Q:What is the bare minimum orEPTTquantity?

A:Our least orEPTTquantity depends on various motor types, make sure you email us to check. Also, we typically do not acknowledge personal use motor orders.

Q:What is actually your shipping and delivery strategy for motors?

A:For samples and offers significantly less than 100kg, we generally recommend express shipping For hefty offers, we usually propose air transport or sea shipping. But it all relies upon on our customers’ needs.

Q:What certifications do you have?

A:We at present have CE and ROSH certifications.

Q:Can you send out me your cost checklist?

A:Considering that we have hundreds of various merchandise, and value may differ for every distinct specs, we are not ready to provide a price tag checklist. But we can estimate in 24 hours once got your inquirues to make confident you can get the price tag in time.

Q:Can I go to your business?

A:Sure, welcome to go to our organization, but please permit us know at lEPTT two weeks EPTT to aid us make confident no other conferences during the working day you pay a visit to us. Thanks!

Weclome contact with us if have any concerns about this motor or other merchandise!

in Varanasi India sales price shop near me near me shop factory supplier 42mm NEMA 17 0.9 1.8 Degree Permanent Magnet Electric Step Stepper Motor with Hollow Shaft manufacturer best Cost Custom Cheap wholesaler

Having accrued cherished expertise in cooperating with overseas buyers, EPG is a professional producer and exporter that is anxious with the design, advancement and production. We can provide a complete-selection of electrical power transmission products like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. Description:

Action angel:one.eight deg

EPTT dimension: NEMA17 42mm

EPTT torque:.2N.m-.8N.m

Choices:Brake,Encoder,Plantary EPTT box

CE and RoHS approved

Applications

Use for robots stepper motor, electric powered automatic equipment stepping motor, health-related instrument stepping motor, ad instrument stepper motor, lights amp audio equipment stepper motor, printer stepper motor, textile EPTTry stepper motor,CNC router stepper motor,3D Printer stepper motor.

EPTT Specs

| nema17, one.8 diploma | ||||||||

| Model Amount | EPTT torque | Rated Cuttent | Wiring Resisitance | Winding Inductance | Rotor Inertia | Mass | EPTT Size | Connection Method |

| Single Shaft | N.m min | A/Section | Omega/Period @twenty ordmC | Mh/Stage | g.cm sup2 | kg | mm | |

| JT242BP06 | .16 | .six | 6.six | nine.five | 23 | .two | 31 | Connector |

| JT242BP12 | one.two | 1.eight | two.4 | |||||

| JT243BP06 | .25 | .six | 8 | 16.five | 35 | .24 | 35 | |

| JT243BP12 | one.two | 2.1 | four.2 | |||||

| JT244BP12 | .four | 1.2 | two.5 | five.5 | fifty four | .3 | 41 | |

| JT244BP20 | 2 | 1.05 | 2.1 | |||||

| JT245BP12 | .forty eight | one.2 | three.one | eight | 77 | .36 | forty nine | |

| JT245BP20 | two | 1.35 | three.two | |||||

| JT246BP12 | .seventy two | one.two | four | 11 | one hundred ten | .5 | 61 | |

| JT246BP20 | two | one.seventy five | 4 | |||||

| JT243UP12 | .17 | 1.2 | two.four | two.two | 35 | .24 | 35 | |

| JT244UP12 | .28 | one.two | three | three | fifty four | .three | 41 | |

| JT245UP12 | .33 | 1.two | 3.7 | 4.6 | 77 | .36 | 49 | |

| nema17, .9 degree | ||||||||

| Design Variety | EPTT torque | Rated Cuttent | Wiring Resisitance | Winding Inductance | Rotor Inertia | Mass | EPTT Length | Connection Manner |

| Solitary Shaft | N.m min | A/Period | Omega/Period @twenty ordmC | Mh/Period | g.cm sup2 | kg | mm | |

| JT443BP12 | .25 | one.two | 2 | 5 | 35 | .24 | 35 | Connector |

| JT444BP20 | .4 | two | one.1 | three | 54 | .three | forty one | |

| JT445BP20 | .five | two | 1.four | 4 | 77 | .36 | 49 | |

| nema17, one.eight diploma, Brake | ||||||||

| Model Quantity | EPTT torque | Rated Cuttent | Wiring Resisitance | Winding Inductance | Rotor Inertia | Brake static friction torque | Volt/Watt | EPTT Fat |

| Single Shaft | N.m min | A/Section | Omega/Phase @20 ordmC | Mh/Stage | g.cm sup2 | N.m | v/w | kg |

| JT244B20M | .4 | 2 | 1.05 | 2.one | 54 | .five | 24VDC/3.5W | .three |

| JT245B20M | .forty eight | two | 1.35 | 3.2 | seventy seven | .36 | ||

| JT246B20M | .72 | 2 | one.seventy five | 4 | a hundred and ten | .five | ||

in Cabinda Angola sales price shop near me near me shop factory supplier NEMA 17 Geared Step Motor for 3D Printer manufacturer best Cost Custom Cheap wholesaler

We are seeking forward to establishing successful enterprise relationships with new clientele close to the world in the long term. Our AdvantagesProducts Big quantity in Inventory, No MOQ required We comply with all the international specifications, such as ISO9001 and TS16949 standards. If you are interested in any of our products or would like to examine a prospective purchase, you should really feel totally free to speak to us. Stage angel:one.8 deg

EPTT measurement: NEMA17 42mm

EPTT torque:.2N.m-.8N.m

Options:Brake,Encoder,Plantary EPTT box

Description:

1.8 degree/.9 degree Measurement 42mm Hybrid stepper motor.

3D Printer stepper motor

42mm size stepper motor

NEMA17 stepping motor

Modest stepping motors

2 period 42mm stepper motor

CE and RoHS authorized

Apps

Use for robots stepper motor, electrical computerized products stepping motor, health care instrument stepping motor, advertisement instrument stepper motor, lighting amp audio equipment stepper motor, printer stepper motor, textile EPTTry stepper motor,CNC router stepper motor,3D Printer stepper motor.

Design Numbering Program

EPTT Technical specs

| nema17, 1.eight degree | ||||||||

| Model Variety | EPTT torque | Rated Cuttent | Wiring Resisitance | Winding Inductance | Rotor Inertia | Mass | EPTT Length | Link Method |

| Solitary Shaft | N.m min | A/Phase | Omega/Period @20 ordmC | Mh/Period | g.cm sup2 | kg | mm | |

| JT242BP06 | .sixteen | .six | six.six | nine.5 | 23 | .two | 31 | Connector |

| JT242BP12 | 1.two | one.8 | 2.four | |||||

| JT243BP06 | .25 | .6 | 8 | sixteen.five | 35 | .24 | 35 | |

| JT243BP12 | one.2 | two.one | four.2 | |||||

| JT244BP12 | .four | one.2 | 2.five | five.five | fifty four | .3 | 41 | |

| JT244BP20 | two | one.05 | two.one | |||||

| JT245BP12 | .forty eight | 1.two | three.one | 8 | 77 | .36 | forty nine | |

| JT245BP20 | 2 | one.35 | 3.2 | |||||

| JT246BP12 | .72 | 1.two | four | 11 | one hundred ten | .5 | 61 | |

| JT246BP20 | two | one.seventy five | 4 | |||||

| JT243UP12 | .seventeen | one.2 | two.4 | 2.two | 35 | .24 | 35 | |

| JT244UP12 | .28 | one.2 | 3 | three | fifty four | .three | 41 | |

| JT245UP12 | .33 | one.2 | 3.7 | four.six | 77 | .36 | 49 | |

| nema17, .9 diploma | ||||||||

| Model Number | EPTT torque | Rated Cuttent | Wiring Resisitance | Winding Inductance | Rotor Inertia | Mass | EPTT Size | Connection Method |

| One Shaft | N.m min | A/Period | Omega/Phase @twenty ordmC | Mh/Phase | g.cm sup2 | kg | mm | |

| JT443BP12 | .25 | one.two | two | five | 35 | .24 | 35 | Connector |

| JT444BP20 | .4 | two | 1.1 | three | fifty four | .3 | forty one | |

| JT445BP20 | .five | 2 | one.four | four | 77 | .36 | 49 | |

| nema17, 1.eight diploma, Brake | ||||||||

| Model Number | EPTT torque | Rated Cuttent | Wiring Resisitance | Winding Inductance | Rotor Inertia | Brake static friction torque | Volt/Watt | EPTT Excess weight |

| Solitary Shaft | N.m min | A/Stage | Omega/Period @twenty ordmC | Mh/Period | g.cm sup2 | N.m | v/w | kg |

| JT244B20M | .four | 2 | one.05 | two.1 | 54 | .5 | 24VDC/three.5W | .three |

| JT245B20M | .48 | two | 1.35 | three.two | seventy seven | .36 | ||

| JT246B20M | .72 | 2 | 1.seventy five | four | one hundred ten | .five | ||

EPTT Connection Choices

Brake Choices

Plantary Gear Alternatives

EncoEPTTOptions

in Owerri Nigeria sales price shop near me near me shop factory supplier NEMA 17 1.8 Degree Large Stepper Motor for 3D Printer manufacturer best Cost Custom Cheap wholesaler

With thorough requirments, we can also create your particular created solution. Service & Good quality controlWe offer detailed drawings and supply each time required. Meanwhile, our goods are created in accordance to high top quality expectations, and complying with the international superior common criteria. Stage angel:1.8 deg

EPTT dimension: NEMA17 42mm

EPTT torque:.2N.m-.8N.m

Possibilities:Brake,Encoder,Plantary EPTT box

Description:

1.eight degree/.9 diploma Measurement 42mm Hybrid stepper motor.

3D Printer stepper motor

42mm dimensions stepper motor

NEMA17 stepping motor

Little stepping motors

2 phase 42mm stepper motor

CE and RoHS authorized

Applications

Use for robots stepper motor, electric powered automatic equipment stepping motor, healthcare instrument stepping motor, advertisement instrument stepper motor, lighting amp audio products stepper motor, printer stepper motor, textile EPTTry stepper motor,CNC router stepper motor,3D Printer stepper motor.

Product Numbering Technique

EPTT Specifications

| nema17, 1.eight degree | ||||||||

| Model Amount | EPTT torque | Rated Cuttent | Wiring Resisitance | Winding Inductance | Rotor Inertia | Mass | EPTT Duration | Link Mode |

| One Shaft | N.m min | A/Section | Omega/Period @twenty ordmC | Mh/Stage | g.cm sup2 | kg | mm | |

| JT242BP06 | .sixteen | .6 | six.6 | nine.5 | 23 | .2 | 31 | Connector |

| JT242BP12 | one.two | one.8 | two.four | |||||

| JT243BP06 | .twenty five | .6 | 8 | sixteen.five | 35 | .24 | 35 | |

| JT243BP12 | one.2 | two.one | four.2 | |||||

| JT244BP12 | .four | one.two | 2.five | five.5 | fifty four | .3 | forty one | |

| JT244BP20 | 2 | 1.05 | 2.one | |||||

| JT245BP12 | .48 | 1.two | three.1 | eight | 77 | .36 | 49 | |

| JT245BP20 | two | 1.35 | three.2 | |||||

| JT246BP12 | .72 | one.2 | four | eleven | one hundred ten | .5 | 61 | |

| JT246BP20 | 2 | 1.seventy five | 4 | |||||

| JT243UP12 | .17 | 1.two | two.4 | 2.two | 35 | .24 | 35 | |

| JT244UP12 | .28 | 1.two | 3 | three | fifty four | .three | forty one | |

| JT245UP12 | .33 | 1.two | 3.seven | 4.six | 77 | .36 | forty nine | |

| nema17, .nine degree | ||||||||

| Design Number | EPTT torque | Rated Cuttent | Wiring Resisitance | Winding Inductance | Rotor Inertia | Mass | EPTT Length | Connection Mode |

| Solitary Shaft | N.m min | A/Period | Omega/Stage @20 ordmC | Mh/Phase | g.cm sup2 | kg | mm | |

| JT443BP12 | .25 | 1.2 | two | five | 35 | .24 | 35 | Connector |

| JT444BP20 | .four | two | 1.1 | three | fifty four | .three | forty one | |

| JT445BP20 | .five | 2 | one.4 | four | 77 | .36 | 49 | |

| nema17, one.8 degree, Brake | ||||||||

| Model Amount | EPTT torque | Rated Cuttent | Wiring Resisitance | Winding Inductance | Rotor Inertia | Brake static friction torque | Volt/Watt | EPTT Bodyweight |

| One Shaft | N.m min | A/Phase | Omega/Period @twenty ordmC | Mh/Section | g.cm sup2 | N.m | v/w | kg |

| JT244B20M | .four | two | 1.05 | 2.1 | 54 | .5 | 24VDC/three.5W | .3 |

| JT245B20M | .48 | two | 1.35 | three.two | 77 | .36 | ||

| JT246B20M | .seventy two | 2 | one.75 | 4 | 110 | .5 | ||

EPTT Connection Alternatives

Brake Options

Plantary Gear Possibilities

EncoEPTTOptions

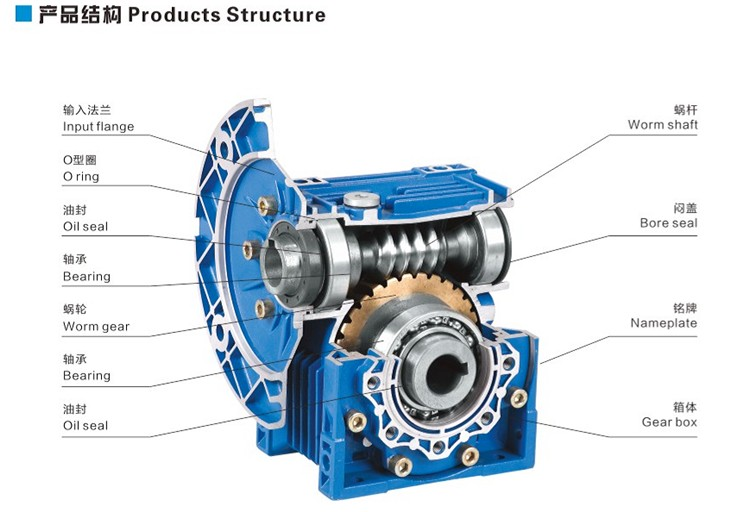

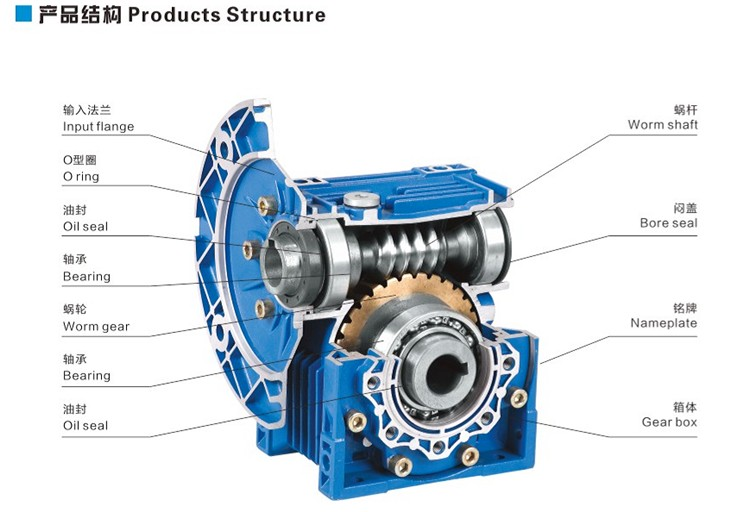

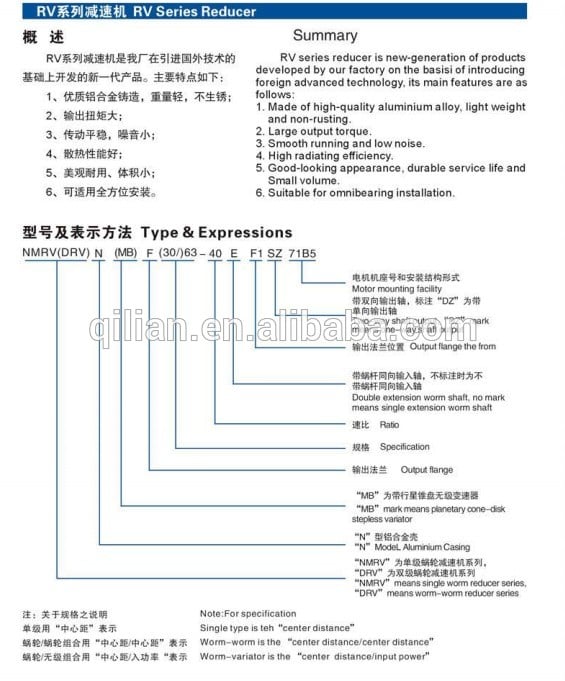

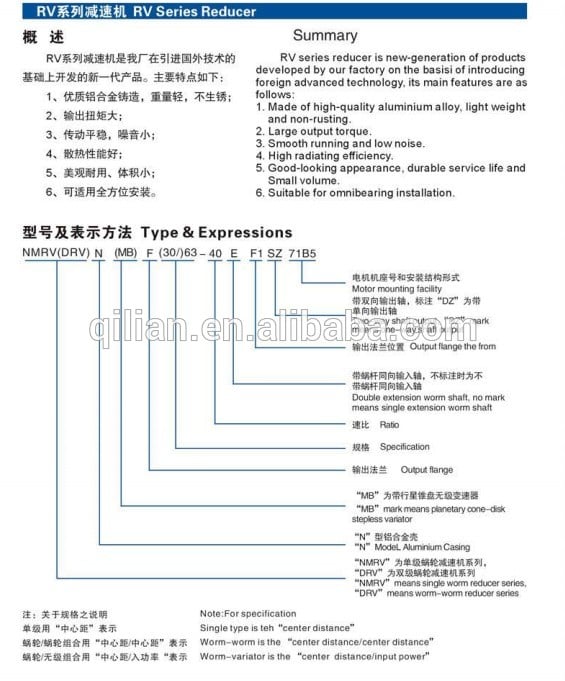

Best China manufacturer & factory ratio 7.5 1 NMRV050 worm gear box 14mm 19mm input shaft 90 degree worm gear speed reducer NEMA for serve motor With high quality best price

Full use has been made of all kinds of advanced techniques and technology to reach excelsior manufacturing.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

worm

- Output Torque:

-

4~2320Nm

- Input Speed:

-

0.28~4.7rpm

- Output Speed:

-

1400rpm(4pole)

PTO Shaft Safety Tips The most common PTO related injuries tend to occur when articles of loose clothing become entangled in the shaft. When operating the PTO, never reach over the shaft for any reason and avoid wearing loose-fitting clothing. Injury can occur quickly, providing the operator little time to react, and in some cases resulting in death.

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

RAL9006(grey) OR RAL5010(blue)

- Label:

-

Customer requirement

- Material of housing:

-

Aluminum&Cast Iron

- Input Flange:

-

IEC flange for mounting motor

- Customization:

-

Acceptable

- Quality Control System:

-

ISO9001:2008

Supply Ability

- Supply Ability:

- 20000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- Carton + Wooden Case

- Port

- Shanghai/Ningbo port

EPG brand rotocultivator ploughshares in T. line were selected as the Nationwide Rotary Tillage Machinery Industry “Perfect Brand Products” in 2007 by Rotocultivator Branch of China Agricultural Machinery Industry Association.

-

Lead Time

: -

Quantity(Boxes) 1 – 1 >1 Est. Time(days) 15 To be negotiated

Online Customization

ratio 7.5 1 NMRV050 worm gear box 14mm 19mm input shaft 90 degree worm gear speed reducer NEMA for serve motor

Product Description

PRODUCTS CHARACTERISTICS

1. Mad of high-quality aluminum alloy,light weight and non-rusting

2. Large output torque

3. Smooth in running and low in noise,can work long time in dreadful conditions.

4. High in radiating efficiency.

EPG is a company specialized in the manufacture of the speed reducers for industry in general. From this idea, Mr. Alan began his activity in 1997. In small installations, the first gears and carcasses were manufactured and mechanized, while mounting the first reducers from mark EPG. With becoming to the years, we have passed from a small workshop of almost 150 meters to the new installation that occupy a surface of 5.800 meters.5. Good-looking in appearance,durable in service life and small in volume.

6. Suitable for omnibearing installation.

|

Type: |

Worm Gear Speed Reducer/ Gearbox |

|

Model No.: |

NMRV025, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

|

Ratio: |

5,7.5,10,15,20,25,30,40,50,60,80,100 |

|

Color: |

Blue(Ral5010)/Silver Grey (RAL9006) Or On Customer Request |

|

Material: |

Housing: Size 25-110 Is Aluminum Alloy, Size 110-150 Is Cast-Iron |

|

Worm Wheel: ZCuSn10Pb1 |

|

|

Worm:20Cr |

|

|

Pinion:Tin Bronze |

|

|

Output Shaft: Steel-45# |

|

|

Usages: |

Industrial Machine: Food Stuff, Ceramics, Chemical, Packing, Dyeing,Wood working, Glass. |

|

IEC Flange: |

IEC Standard Flange Or On Customer Request |

Company Information

Certifications

Our Services

Packaging & Shipping

Related Products

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us