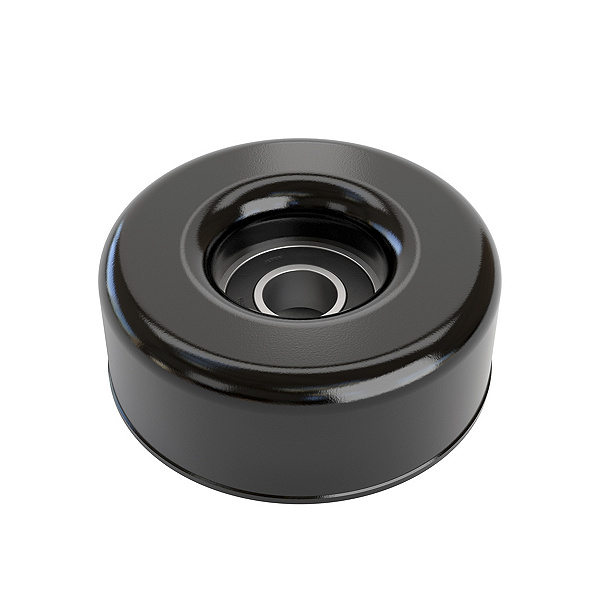

2.625″ I.D., 3.628″ O.D., 0.375″ wide

Also fits the follow gas, LP, diesel engines: 251, 267, 284, 301, 336, 377, 401, 451 and 504 Cubic Inch.

2.625″ I.D., 3.628″ O.D., 0.375″ wide

4-1/32″ O.D.

3-7/16″ I.D.

3/8″ Thick

Cork

Oil Seal

Description

– Fits: [ 4W220, 7010, 7020, 7030, 7040, 7045, 7050, 7060, 7080, 7580, 8010, 8030, 8050, 8070, 8550 (all used as a power director clutch oil seal) ]; Replaces: 270128, 70270128

– Matches: [ S, SC, SC-3, SC-4, SO (As a differential brake pinion shaft seal) ], [ Super 400, 1030, 1030 Comfort King, 1031, 1032, 1070, 1090, 1170, 1175, 1200TK, 1270, 1370, 1470, 1570, 2090, 2290, 2294, 2390, 2394, 2470, 2590, 2594, 2670, 3394, 3594, 400, 401, 402, 403, 405, 410, 411, 412, 413, 414, 415, 425, 4490, 4494, 4690, 500, 520, 610, 620, 700, 701, 701B, 702, 702B, 703, 703B, 705, 705B, 710, 710B, 711, 711B, 712, 712B, 713, 713B, 715, 715B, 725B, 730, 730CK, 731, 732, 733, 734, 740, 741, 742, 743, 744, 770, 800B, 801, 801B, 802, 802B, 803, 803B, 805B, 810, 810B, 811, 811B, 812, 812B, 813, 813B, 815, 815B, 830, 830 Comfort King, 831, 832, 833, 840, 841, 842, 843, 870, 900, 900B, 910, 920B, 930, 930 Comfort and ease King, 931, 932, 940, 941, 970 (all utilized as a front side crankshaft essential oil seal) ], [ Cruz Air: 45, 45B (all utilized as a front crankshaft oil seal) ], [ Excavator : 40D, 40E (all utilized as a front crankshaft essential oil seal) ], Industrial: W7C (all used as a front side crankshaft essential oil seal on rubber tired loaders); Replaces: A157044, A23433, A24715, A27838, A40349, A57342, A62049, O3866Abs, O8583AB, O9708Abs, T34263

– Matches: [ 1000, 1010, 1060, 1160 (all used as a front crankshaft oil seal) ]

– Suits: [ 420 Loader / Backhoe, 600 Skidder, 800 Skidder (all used as a front crankshaft essential oil seal) ], Cable Layer: 475 (all used as a front side crankshaft oil seal), [ Crawler: 1150, 1150B, 1150C, 1150D, 1155D, 1450, 1450B, 1455B, 750, 850, 850B, 850C (all used as a front crankshaft essential oil seal) ], [ Excavator : 1080, 1080B, 1280, 1280B, 50E, 880B, 880 Excavator, 980, 980B (all utilized as a front crankshaft essential oil seal) ], [ Industrial: 680B, 680C, 680CK, 680E, 680G, 680H, 780B, W10, W10B, W10C, W10E, W12, W14, W14H, W18, W18B, W20, W20B, W20C, W24, W24B, W24C, W26B, W30, W36, W7, W7E, W8B, W8C, W8Electronic, W9, W9A, W9B, W9C, W9E (all used as a front side crankshaft essential oil seal on rubber exhausted loaders) ], [ Tree Skidder: 600 Skidder, 800 Skidder (all used as a front crankshaft oil seal) ]

– Fits: [ 2094, 3294, 4694 (all used as a front crankshaft oil seal) ]

– Fits: 9400 (used as a principal counter shaft gearbox oil seal)

– Suits: 400 (all used as a PTO belt pulley shaft essential oil seal), Crawler: 450C (up to SN:  246900; all used as a steering clutch manifold oil seal), Loader / Backhoe: 210C (SN: 760731 and up; used as an inner rear axle essential oil seal), [ 300D, 310, 310A, 310B, 310C, 310D, 315C, 315D, 401, 401C, 401D, 410, 480A, 480B, 480C, 482C (all used as an inner back axle oil seal) ], 410B (up to SN: 704001; used as an inner rear axle oil seal)

246900; all used as a steering clutch manifold oil seal), Loader / Backhoe: 210C (SN: 760731 and up; used as an inner rear axle essential oil seal), [ 300D, 310, 310A, 310B, 310C, 310D, 315C, 315D, 401, 401C, 401D, 410, 480A, 480B, 480C, 482C (all used as an inner back axle oil seal) ], 410B (up to SN: 704001; used as an inner rear axle oil seal)

– [ 1020, 2010, 2030, 2040, 2141, 2240, 2520, 2541, 2941, 3141, 3641, 4320 (all used as a PTO belt pulley shaft oil seal) ], 4020 (up to SN: 200999; used because a PTO belt pulley shaft oil seal), [ Crawler: 550, 555 (up to SN: 246900; all used as a steering clutch manifold oil seal) ], Loader / Backhoe: 315CH (all utilized as an inner rear axle oil seal); Replaces: AT124396, AT16887

– Fits: 55 (Sn: 3023 & up, As a diff. brake gear shaft seal); Replaces: 15874X

– Matches: [ G1000 Vista, G1050, G1350, G1355, G900, G950, G955 (As a 2 wheel drive inner front wheel seal) ]; Replaces: 10A26954

– Matches: [ 1865, 1870, 2055, 2155, 2255, 2270 (As a 2 wheel drive internal front wheel seal) ], [ 77, 770 (As a brake pinion shaft (bull pinion) seal) ]; Replaces: 1M-1110, 1M1110, M1110

– Fits: [ 100, 120, 125, 140, 145, 160, 2-135, 2-150, 2-155, 2-180 (As a 2 wheel drive internal front wheel seal) ]

Belt Pulley Gasket

Description

– Fits: WC, WD, WD45, WF; Replaces: 70202289

3.43″ x 1.93″

3.43″ x 1.93″ 4 in. OD

4 in. OD found in.

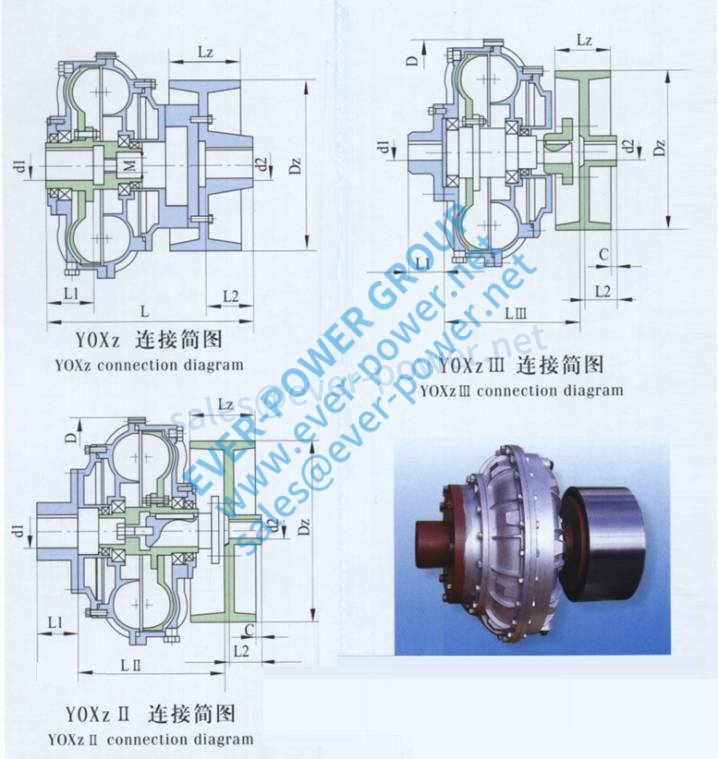

found in. shed device and functions like a turbine. Power transmission is proportional to the fill stage in the functioning circuit. As a consequence of the mechanical separation of the travel and pushed sides, the hydrodynamic coupling transfers the electricity put on-totally free and dampens the torsional vibration and torque shocks in the travel chain simultaneously.

shed device and functions like a turbine. Power transmission is proportional to the fill stage in the functioning circuit. As a consequence of the mechanical separation of the travel and pushed sides, the hydrodynamic coupling transfers the electricity put on-totally free and dampens the torsional vibration and torque shocks in the travel chain simultaneously. to 11000 KW

to 11000 KW of transport parts, hydraulic components, oil coolers and our very own monitoring system the Beegle. Do you want to know more about a product or have you got a question? Our specific sales engineers will always be happy to help you find the best product necessary for you technical problem. Feel free to e mail us if you possess concerns or seek information.

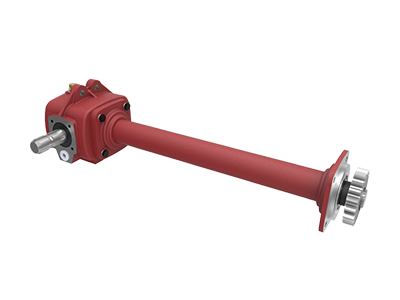

of transport parts, hydraulic components, oil coolers and our very own monitoring system the Beegle. Do you want to know more about a product or have you got a question? Our specific sales engineers will always be happy to help you find the best product necessary for you technical problem. Feel free to e mail us if you possess concerns or seek information. way to locate your exact Omni Gear substitution gearbox is to use the six-digit assembly quantity stamped on each and every Omni Equipment gearbox.

way to locate your exact Omni Gear substitution gearbox is to use the six-digit assembly quantity stamped on each and every Omni Equipment gearbox. and belt.

and belt. add a nice touch of style!

add a nice touch of style! for your vacuum pump, and if you use our oil throughout the full guarantee period and follow essential oil change recommendations, we dual your warranty to two years!

for your vacuum pump, and if you use our oil throughout the full guarantee period and follow essential oil change recommendations, we dual your warranty to two years! types. Would you like to discover more about our range of geared motors?

types. Would you like to discover more about our range of geared motors? potential drawback of this, however, is that backlash can make it harder to attain accurate positioning.

potential drawback of this, however, is that backlash can make it harder to attain accurate positioning. individual velocity control requirements. Two adjustable rate drive models include a reversing lever that allows clockwise, neutral and counter-clockwise operation.

individual velocity control requirements. Two adjustable rate drive models include a reversing lever that allows clockwise, neutral and counter-clockwise operation. drives are easy to install and simple to operate. Their higher level of efficiency also provides them a far more positive environmental impact.

drives are easy to install and simple to operate. Their higher level of efficiency also provides them a far more positive environmental impact. maintain these on the shelf as regular stock bores. However, we can supply sprockets with completed bores thanks to our fast-reaction internal industrial machine store. Typically our sprockets are manufactured out of 304 quality stainless, but 316 as well as a few various other grades are available upon request.

maintain these on the shelf as regular stock bores. However, we can supply sprockets with completed bores thanks to our fast-reaction internal industrial machine store. Typically our sprockets are manufactured out of 304 quality stainless, but 316 as well as a few various other grades are available upon request. low rpm, he or she will struggle as

low rpm, he or she will struggle as with reinforced hollow bore.

with reinforced hollow bore. driven system’s stop-start operation. Furthermore, water and chemical substances are evenly distributed over the crop.

driven system’s stop-start operation. Furthermore, water and chemical substances are evenly distributed over the crop. gearbox motors when from the same producer. The increased heat results in lower effectiveness and the parts ultimately wearing out.

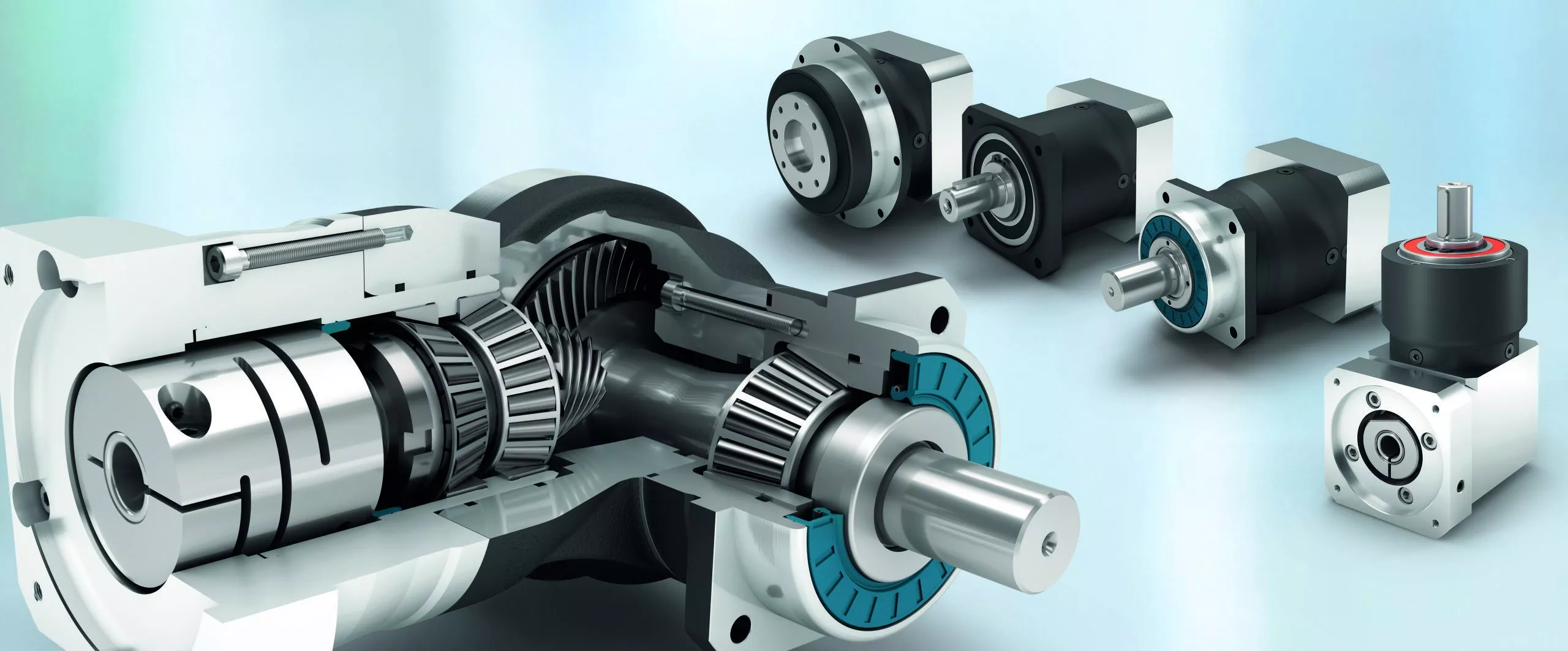

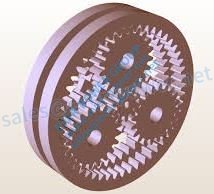

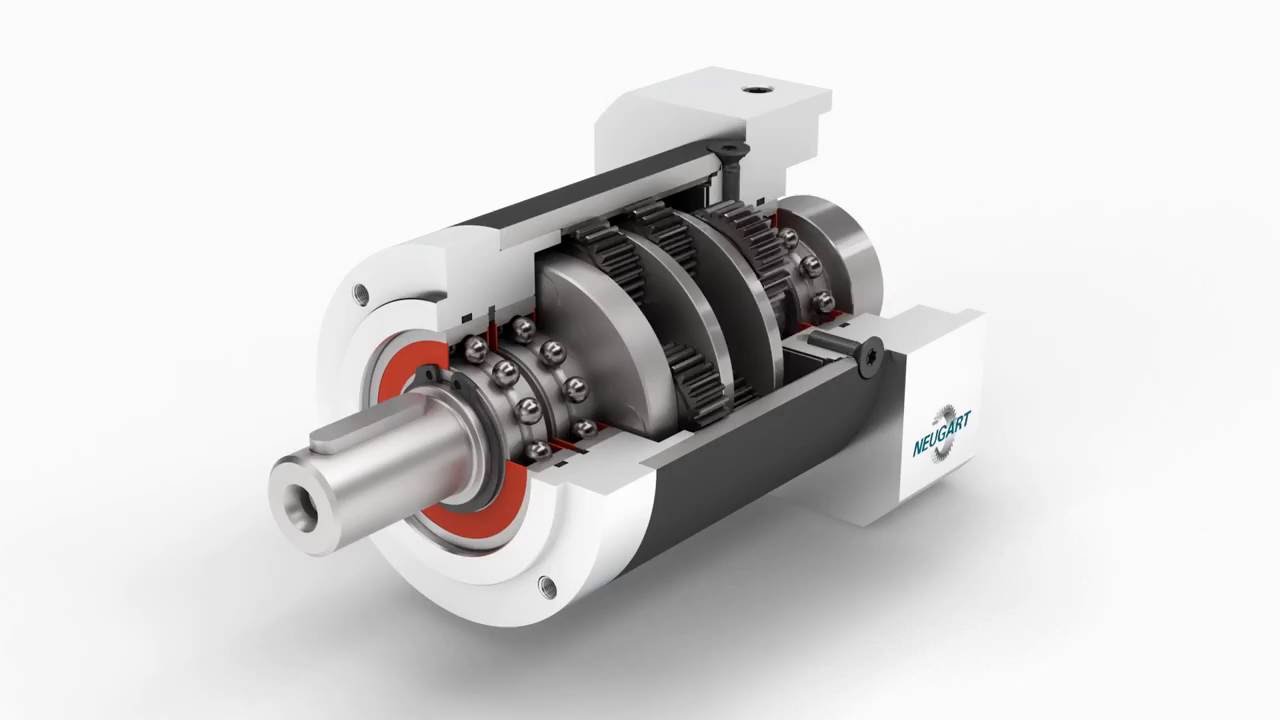

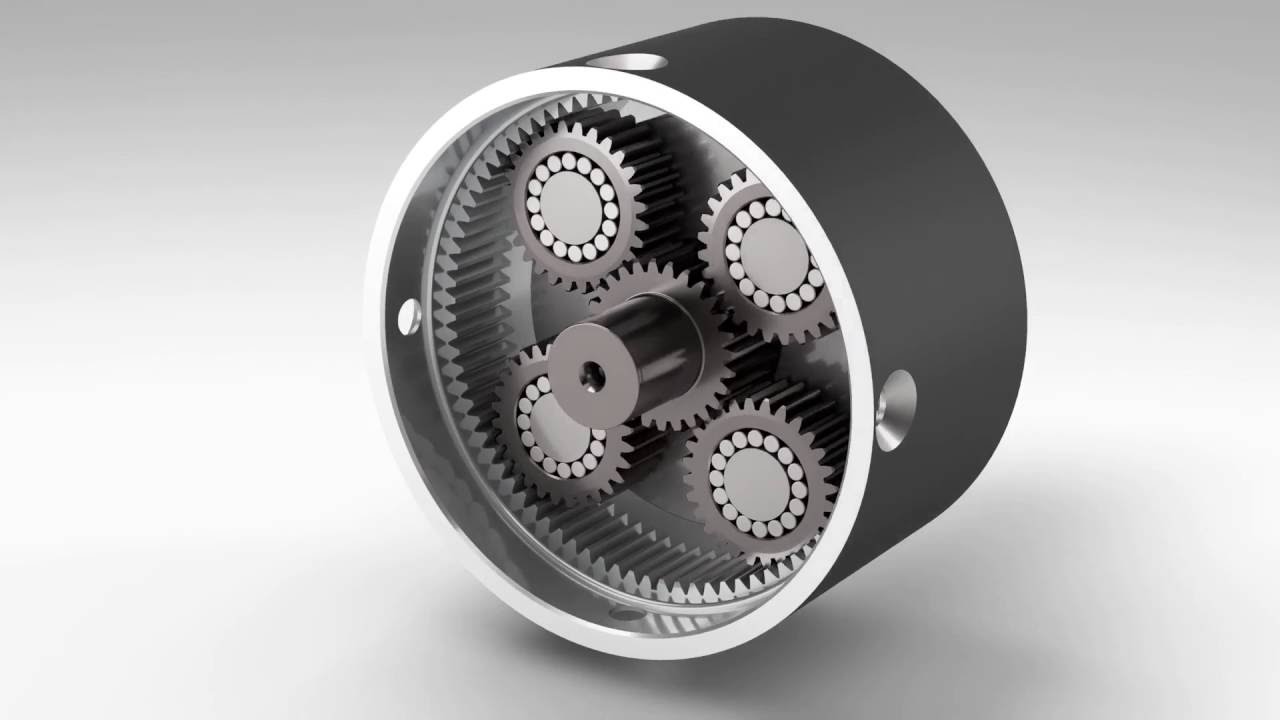

gearbox motors when from the same producer. The increased heat results in lower effectiveness and the parts ultimately wearing out. A carrier links the centres of both gears and rotates to carry one gear, called the earth gear or world pinion, around the additional, called the sun gear or sun wheel. The planet and sun gears mesh to ensure that their pitch circles roll without slide. A spot on the pitch circle of the planet gear traces an epicycloid curve. In this simplified case, the sun gear is fixed and the planetary equipment(s) roll around sunlight gear.

A carrier links the centres of both gears and rotates to carry one gear, called the earth gear or world pinion, around the additional, called the sun gear or sun wheel. The planet and sun gears mesh to ensure that their pitch circles roll without slide. A spot on the pitch circle of the planet gear traces an epicycloid curve. In this simplified case, the sun gear is fixed and the planetary equipment(s) roll around sunlight gear. high precision and torque.

high precision and torque.  Quite a few DC Motors could be complimented with among our Worm Gearheads. ISL Products will continue to work with you to create and produce a Worm Gear Engine that may optimize the functionality of your unique application.

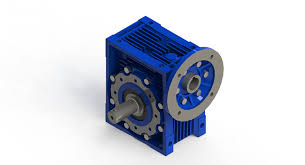

Quite a few DC Motors could be complimented with among our Worm Gearheads. ISL Products will continue to work with you to create and produce a Worm Gear Engine that may optimize the functionality of your unique application. 1/6 – 25 HP

1/6 – 25 HP sliding contact reduces efficiency, it provides extremely quiet operation. (The utilization of dissimilar metals for the worm and gear also contributes to quiet procedure.) This creates worm gears suitable for use where sound should be minimized, such as for example in elevators. In addition, the use of a softer material for the gear implies that it can absorb shock loads, like those skilled in large equipment or crushing machines.

sliding contact reduces efficiency, it provides extremely quiet operation. (The utilization of dissimilar metals for the worm and gear also contributes to quiet procedure.) This creates worm gears suitable for use where sound should be minimized, such as for example in elevators. In addition, the use of a softer material for the gear implies that it can absorb shock loads, like those skilled in large equipment or crushing machines. practically all flat surfaces and prevents foreign matter accumulation or position fluid

practically all flat surfaces and prevents foreign matter accumulation or position fluid good shaft’s rotation. Straight pearly whites have similar features to spur gears and possess a large affect when engaged. They produce vibration and noise very similar to a spur equipment due to their straight tooth. The bevel gear has many different applications such as in a hands drill where they have the added good thing about increasing the velocity of rotation of the chuck and this can help you drill a range of supplies. Bevel gears are also within printing presses and inspection devices where they are manage at many speeds. Nylon bevel gears are usually used in electrical products such as for example DVD players.

good shaft’s rotation. Straight pearly whites have similar features to spur gears and possess a large affect when engaged. They produce vibration and noise very similar to a spur equipment due to their straight tooth. The bevel gear has many different applications such as in a hands drill where they have the added good thing about increasing the velocity of rotation of the chuck and this can help you drill a range of supplies. Bevel gears are also within printing presses and inspection devices where they are manage at many speeds. Nylon bevel gears are usually used in electrical products such as for example DVD players. this case the worm truly behaves as if it had only 1 tooth around its circumference.

this case the worm truly behaves as if it had only 1 tooth around its circumference. substitute saving the client time and money.

substitute saving the client time and money. factor.

factor.

ISO14001, OHSAS18001

ISO14001, OHSAS18001 alignment of horizontal and vertical bases.

alignment of horizontal and vertical bases. ended or dual ended shafts to assemble in these gearboxes. All gearbox shafts are given keys and retainer bands.

ended or dual ended shafts to assemble in these gearboxes. All gearbox shafts are given keys and retainer bands. Combine the helical-worm gear unit with this AC motors:

Combine the helical-worm gear unit with this AC motors: develop an all-new design that delivers the performance you need. Ask for a quote on a custom miniature gearbox or contact us to discuss your unique requirements.

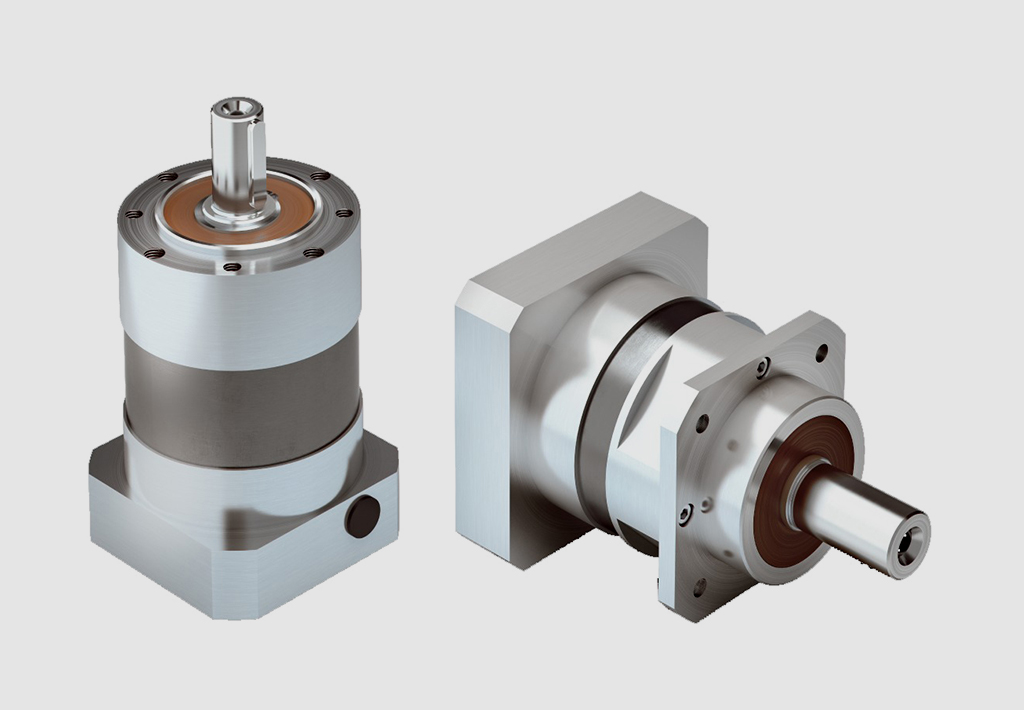

develop an all-new design that delivers the performance you need. Ask for a quote on a custom miniature gearbox or contact us to discuss your unique requirements. the same size. All planetary carriers are manufactured as a cage made from solid material. This increases quiet operating characteristics while at exactly the same time improving positioning accuracy and reducing backlash. An additional shaft sealing ring ensures maximum dirt and splash water safety in accordance with protection class IP65 in all lines.

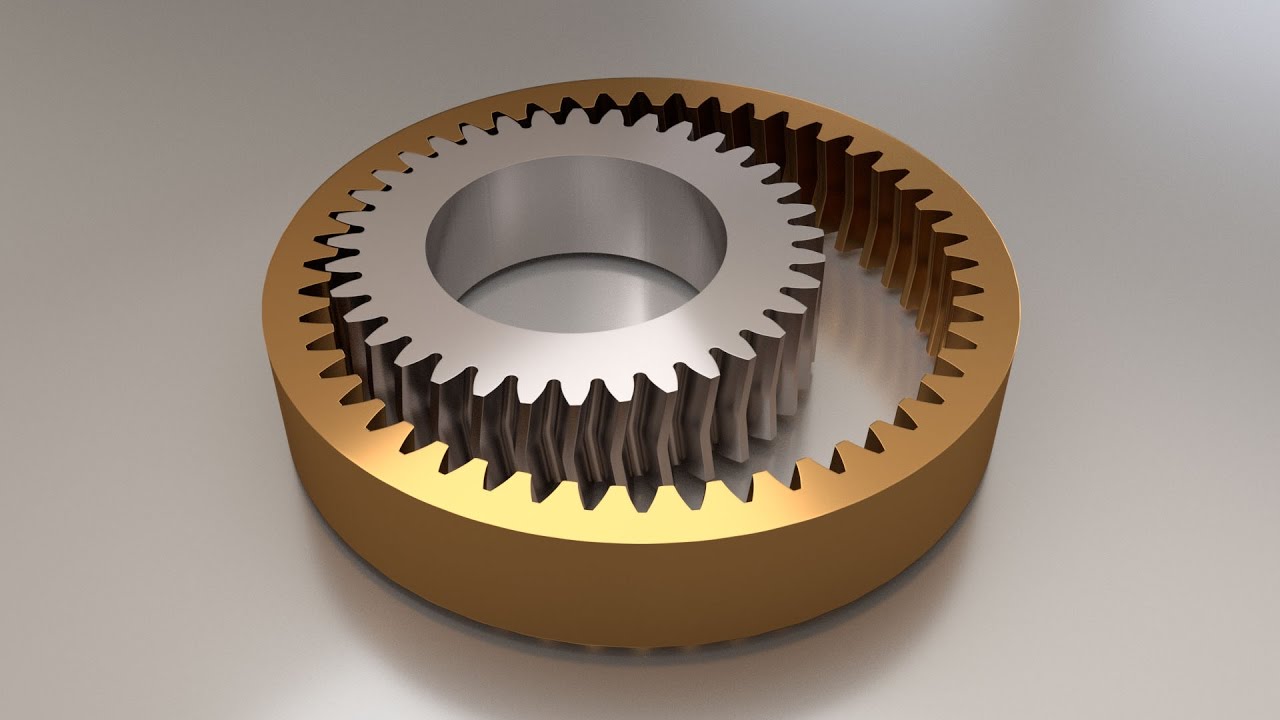

the same size. All planetary carriers are manufactured as a cage made from solid material. This increases quiet operating characteristics while at exactly the same time improving positioning accuracy and reducing backlash. An additional shaft sealing ring ensures maximum dirt and splash water safety in accordance with protection class IP65 in all lines. 90 degrees, the axial pitch of the worm and the circular pitch of the worm wheel will be equal. It is not uncommon for fine pitch worm units to have the size of the teeth specified when it comes to diametral pitch. The pressure angles employed depend upon the business lead angles and must be large enough to prevent undercutting the worm wheel the teeth. To provide backlash, it is customary to slim the teeth of the worm, however, not the teeth of the worm equipment.

90 degrees, the axial pitch of the worm and the circular pitch of the worm wheel will be equal. It is not uncommon for fine pitch worm units to have the size of the teeth specified when it comes to diametral pitch. The pressure angles employed depend upon the business lead angles and must be large enough to prevent undercutting the worm wheel the teeth. To provide backlash, it is customary to slim the teeth of the worm, however, not the teeth of the worm equipment. gears are manufactured for some of the very most demanding customers in the aerospace, security, and medical industries of today.

gears are manufactured for some of the very most demanding customers in the aerospace, security, and medical industries of today. for speed reduction and raising the torque for electrical engine drives. You can tend to attach your NEMA engine to the reducer by using the NEMA C experience flange or work with a coupling. In the event that you desire a coupling for the output or input shaft observe our coupling section for selecting a coupling. We offer four assemblies left palm and right palm and double output shaft and shaft input and shaft result. Interchangeable with many worm gear manufactures. See info sheet in product overview for diamensions. Unless you see your type, you should Contact Us.

for speed reduction and raising the torque for electrical engine drives. You can tend to attach your NEMA engine to the reducer by using the NEMA C experience flange or work with a coupling. In the event that you desire a coupling for the output or input shaft observe our coupling section for selecting a coupling. We offer four assemblies left palm and right palm and double output shaft and shaft input and shaft result. Interchangeable with many worm gear manufactures. See info sheet in product overview for diamensions. Unless you see your type, you should Contact Us. and tooth cutting after the outside rim is usually cast around the center of the blank.

and tooth cutting after the outside rim is usually cast around the center of the blank. knowledgeable in serious equipment or crushing machines.

knowledgeable in serious equipment or crushing machines. performance features and simplified maintenance. The usage of express of the skill helical and worm equipment combinations affords optimum efficiency fulfilling a multitude of ratio requirements. The EP is normally functionally interchangeable with the majority of major manufacturer’s drives.

performance features and simplified maintenance. The usage of express of the skill helical and worm equipment combinations affords optimum efficiency fulfilling a multitude of ratio requirements. The EP is normally functionally interchangeable with the majority of major manufacturer’s drives. a housing with some bands that limit leakage. A breather can be a connect with a hole that is mounted in the gear housing allowing airflow and relieve inner pressure.

a housing with some bands that limit leakage. A breather can be a connect with a hole that is mounted in the gear housing allowing airflow and relieve inner pressure. according to customer anticipations and in the highest quality. Learn more about it here.

according to customer anticipations and in the highest quality. Learn more about it here. the guts distance between gears. As for pre-loading, this is often done utilizing a spring mechanism to hold the gears firmly set up. This also eliminates the play between your gear teeth and therefore eliminates backlash.

the guts distance between gears. As for pre-loading, this is often done utilizing a spring mechanism to hold the gears firmly set up. This also eliminates the play between your gear teeth and therefore eliminates backlash. delicate acceleration adjustment by utilizing a big speed reduction is needed. When you can rotate the worm gear by worm, it is generally extremely hard to rotate worm utilizing the worm gear. This is called the self locking feature. The self locking feature cannot always be assured and another method is recommended for accurate positive reverse prevention.

delicate acceleration adjustment by utilizing a big speed reduction is needed. When you can rotate the worm gear by worm, it is generally extremely hard to rotate worm utilizing the worm gear. This is called the self locking feature. The self locking feature cannot always be assured and another method is recommended for accurate positive reverse prevention. in Fig. 1. A two-stage system controlled by a two- stage thermostat enables more water to be applied on excessively warm, bright days. Temperature settings ought to be 5-10°F apart.

in Fig. 1. A two-stage system controlled by a two- stage thermostat enables more water to be applied on excessively warm, bright days. Temperature settings ought to be 5-10°F apart. enables more water to be employed on excessively warm, shiny days. Temperature settings ought to be 5-10°F apart.

enables more water to be employed on excessively warm, shiny days. Temperature settings ought to be 5-10°F apart. right size. Make sure that you add the set screw to hold the junctions tightly together. Place the pipe onto the plastic-type material that is lying out on the bottom. From there you will roll the pipe with the plastic-type until you have the beginnings of a roll-up forming.

right size. Make sure that you add the set screw to hold the junctions tightly together. Place the pipe onto the plastic-type material that is lying out on the bottom. From there you will roll the pipe with the plastic-type until you have the beginnings of a roll-up forming. DC bus turns into “around” 650VDC. The actual voltage will depend on the voltage degree of the AC line feeding the drive, the level of voltage unbalance on the energy system, the motor load, the impedance of the energy system, and any reactors or harmonic filters on the drive.

DC bus turns into “around” 650VDC. The actual voltage will depend on the voltage degree of the AC line feeding the drive, the level of voltage unbalance on the energy system, the motor load, the impedance of the energy system, and any reactors or harmonic filters on the drive. advanced microprocessors has allowed the VFD works as an extremely versatile device that not only controls the speed of the engine, but protects against overcurrent during ramp-up and ramp-down conditions. Newer VFDs also provide ways of braking, power boost during ramp-up, and a number of handles during ramp-down. The largest savings that the VFD provides is usually that it can ensure that the motor doesn’t pull extreme current when it begins, therefore the overall demand element for the entire factory can be controlled to keep the domestic bill as low as possible. This feature alone can provide payback more than the cost of the VFD in less than one year after purchase. It is important to keep in mind that with a traditional motor starter, they’ll draw locked-rotor amperage (LRA) if they are starting. When the locked-rotor amperage takes place across many motors in a manufacturing plant, it pushes the electrical demand too high which often outcomes in the plant paying a penalty for all the electricity consumed during the billing period. Because the penalty may become just as much as 15% to 25%, the cost savings on a $30,000/month electric costs can be utilized to justify the buy VFDs for practically every motor in the plant actually if the application might not require operating at variable speed.

advanced microprocessors has allowed the VFD works as an extremely versatile device that not only controls the speed of the engine, but protects against overcurrent during ramp-up and ramp-down conditions. Newer VFDs also provide ways of braking, power boost during ramp-up, and a number of handles during ramp-down. The largest savings that the VFD provides is usually that it can ensure that the motor doesn’t pull extreme current when it begins, therefore the overall demand element for the entire factory can be controlled to keep the domestic bill as low as possible. This feature alone can provide payback more than the cost of the VFD in less than one year after purchase. It is important to keep in mind that with a traditional motor starter, they’ll draw locked-rotor amperage (LRA) if they are starting. When the locked-rotor amperage takes place across many motors in a manufacturing plant, it pushes the electrical demand too high which often outcomes in the plant paying a penalty for all the electricity consumed during the billing period. Because the penalty may become just as much as 15% to 25%, the cost savings on a $30,000/month electric costs can be utilized to justify the buy VFDs for practically every motor in the plant actually if the application might not require operating at variable speed. become positive or unfavorable at will and can hence generate any frequency that people want. So, we are able to make any phase maintain positivity, negative, or zero.

become positive or unfavorable at will and can hence generate any frequency that people want. So, we are able to make any phase maintain positivity, negative, or zero.  polyvinyl.

polyvinyl. have to bring air flow price up. Besides, the soft movements caused by the supporters’ airflow also promote the strengthening of the vegetation’ stems and roots.

have to bring air flow price up. Besides, the soft movements caused by the supporters’ airflow also promote the strengthening of the vegetation’ stems and roots. not a single type of plastic that is most effective for a roll-up side. Rather there are a number of options with varying levels of durability, light tranny, and expected life.

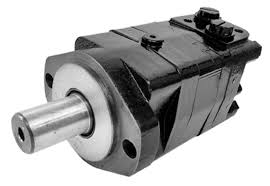

not a single type of plastic that is most effective for a roll-up side. Rather there are a number of options with varying levels of durability, light tranny, and expected life.  electric motor and a hydraulic pump are extremely similar. Because of this, some hydraulic pumps with set displacement volumes may also be used as hydraulic motors. A hydraulic motor works the other way round as it converts hydraulic energy into mechanical energy: a rotating shaft. It uses hydraulic pressure and movement to generate the mandatory torque and rotation. The energy produced by a hydraulic motor is determined by the circulation and pressure drop of the motor.

electric motor and a hydraulic pump are extremely similar. Because of this, some hydraulic pumps with set displacement volumes may also be used as hydraulic motors. A hydraulic motor works the other way round as it converts hydraulic energy into mechanical energy: a rotating shaft. It uses hydraulic pressure and movement to generate the mandatory torque and rotation. The energy produced by a hydraulic motor is determined by the circulation and pressure drop of the motor. maintenance options for motor needs.

maintenance options for motor needs. two front tires through the drive axles. The engine, transmission, and extra hardware is all positioned in the front side of the car.

two front tires through the drive axles. The engine, transmission, and extra hardware is all positioned in the front side of the car. the greenhouse plastic and onto the roll bar. While there are various sizes of snap clamps offered, the hottest are those that fit over best 1.315″ OD (1 3/8″ top rail) tubing. Just click here to check the pricing of snap clamp

the greenhouse plastic and onto the roll bar. While there are various sizes of snap clamps offered, the hottest are those that fit over best 1.315″ OD (1 3/8″ top rail) tubing. Just click here to check the pricing of snap clamp arm or torque limiter.

arm or torque limiter. To see a complete summary of

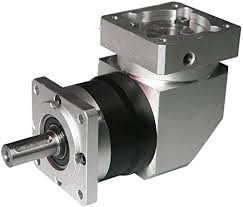

To see a complete summary of  developed for make use of with the latest servo motors in applications that demand exact positioning and repeatability.

developed for make use of with the latest servo motors in applications that demand exact positioning and repeatability. worm speed reducers. Worm equipment reducers are used for speed decrease and raising the torque for electric electric motor drives. You can decide to mount your NEMA electric motor to the reducer utilizing the NEMA C face flange or use a coupling. If you want a coupling for the output or input shaft find our coupling section for choosing the coupling. We offer four assemblies left hands and right hands and double output shaft and shaft insight and shaft output. Interchangeable with many worm gear manufactures. Find data sheet in product overview for diamensions. Unless you see your type, please Contact Us.

worm speed reducers. Worm equipment reducers are used for speed decrease and raising the torque for electric electric motor drives. You can decide to mount your NEMA electric motor to the reducer utilizing the NEMA C face flange or use a coupling. If you want a coupling for the output or input shaft find our coupling section for choosing the coupling. We offer four assemblies left hands and right hands and double output shaft and shaft insight and shaft output. Interchangeable with many worm gear manufactures. Find data sheet in product overview for diamensions. Unless you see your type, please Contact Us.  Rate Decrease; Fast Blinking = Reduced Velocity Setting

Rate Decrease; Fast Blinking = Reduced Velocity Setting inertia in gearbox selection.

inertia in gearbox selection. maintenance. A broad range of reduction ratios suit an even broader selection of specifications, while a variety of input shaft configurations maximize flexibility. In addition, the number of products that complement this series of gear drives make it a perfect choice for today’s industrial distributor.

maintenance. A broad range of reduction ratios suit an even broader selection of specifications, while a variety of input shaft configurations maximize flexibility. In addition, the number of products that complement this series of gear drives make it a perfect choice for today’s industrial distributor. steel gear train and output shaft

steel gear train and output shaft can easily build up inside the motor to harmful levels.

can easily build up inside the motor to harmful levels. Rated input

Rated input improve rigidity and antiknock

improve rigidity and antiknock swiftness reducers. These gearboxes are created to manage varying loads with little backlash. Planetary equipment reducers operate more quietly than parallel shaft reducers. With 18 ratio options which range from 5:1 to 1000:1, we’ve a solution to suit your needs.

swiftness reducers. These gearboxes are created to manage varying loads with little backlash. Planetary equipment reducers operate more quietly than parallel shaft reducers. With 18 ratio options which range from 5:1 to 1000:1, we’ve a solution to suit your needs. engineered for encoder applications, Ever-Power micro inline spur gear drives are available in two frame sizes, and are rated for speeds up to 3,000 RPM. Light weight aluminum housings and stainless steel gears and shafts make these inline spur gearboxes tough and corrosion resistant, for your the majority of demanding applications.

engineered for encoder applications, Ever-Power micro inline spur gear drives are available in two frame sizes, and are rated for speeds up to 3,000 RPM. Light weight aluminum housings and stainless steel gears and shafts make these inline spur gearboxes tough and corrosion resistant, for your the majority of demanding applications. a zero backlash gearbox. The speed reducers are expensive, that reason their use is bound to automation solutions where efficiency and high precision are important to the level the cost ceases to be an issue.

a zero backlash gearbox. The speed reducers are expensive, that reason their use is bound to automation solutions where efficiency and high precision are important to the level the cost ceases to be an issue. optimized housings of the helical bevel gears distinguish themselves by being machined on all sides and are therefore ready for a variety of installation options and applications. Various regular shaft executions and the double chamber shaft seals are ready for use.

optimized housings of the helical bevel gears distinguish themselves by being machined on all sides and are therefore ready for a variety of installation options and applications. Various regular shaft executions and the double chamber shaft seals are ready for use. The materials and items use pass all the assessments laid down by the latest international standards, such as for example UNI EN ISO 9001.

The materials and items use pass all the assessments laid down by the latest international standards, such as for example UNI EN ISO 9001. Radial Loads provided by High Precision Taper Roller Bearings.

Radial Loads provided by High Precision Taper Roller Bearings. power is necessary than the system on the tractor can provide.

power is necessary than the system on the tractor can provide. motion is used in the purple result shaft via rollers or pins that interface to the holes in the disk. Like planetary gearing, the result shaft rotates in the contrary direction to the input shaft. Because the person parts are well-suited to 3D printing, this opens the entranceway to easily prototyping customized designs and gearing ratios.

motion is used in the purple result shaft via rollers or pins that interface to the holes in the disk. Like planetary gearing, the result shaft rotates in the contrary direction to the input shaft. Because the person parts are well-suited to 3D printing, this opens the entranceway to easily prototyping customized designs and gearing ratios. RomaxDesigner models may include spur and helical gears, and with the perpendicular-axis module, bevel and hypoid gears. The base software models gears with enough detail to investigate their effects on the rest of the system. Additional modules allow design and ranking to AGMA, DIN and ISO standards. For parallel-axis gears, additional modules permit macrogeometry definition and optimization for manufacturability as well as detailed evaluation of microgeometry for contact stress and transmission mistake. RomaxDesigner graphics are ideal for a variety of reporting illustrations, such as for example system topology and component deflection.

RomaxDesigner models may include spur and helical gears, and with the perpendicular-axis module, bevel and hypoid gears. The base software models gears with enough detail to investigate their effects on the rest of the system. Additional modules allow design and ranking to AGMA, DIN and ISO standards. For parallel-axis gears, additional modules permit macrogeometry definition and optimization for manufacturability as well as detailed evaluation of microgeometry for contact stress and transmission mistake. RomaxDesigner graphics are ideal for a variety of reporting illustrations, such as for example system topology and component deflection. and optimum torque (expressed in newton meters, N.m) that can be supported by each of their products. The torque density varies according to the gear reducer. For example, planetary gearboxes have a higher torque density.

and optimum torque (expressed in newton meters, N.m) that can be supported by each of their products. The torque density varies according to the gear reducer. For example, planetary gearboxes have a higher torque density. for info associated to

for info associated to  the ON/OFF key or switch. This causes a clockwise or counter-clockwise rotational movement on the motor program, depending on the desired direction of movement. This prospective customers to a movement of the networked gears and chain to go in the same path as the motor. Consequently, the chain conveyor movements the load through the drive train to the last gear, where off-loading is performed. For unidirectional operations, conveyor systems can also be tailor-made to provide movements to either path. This is accomplished through integrating two or more motors on either end of the conveyor program.

the ON/OFF key or switch. This causes a clockwise or counter-clockwise rotational movement on the motor program, depending on the desired direction of movement. This prospective customers to a movement of the networked gears and chain to go in the same path as the motor. Consequently, the chain conveyor movements the load through the drive train to the last gear, where off-loading is performed. For unidirectional operations, conveyor systems can also be tailor-made to provide movements to either path. This is accomplished through integrating two or more motors on either end of the conveyor program. series of short cylindrical rollers held together by aspect links.It is a simple, reliable, and efficient means of power transmission.

series of short cylindrical rollers held together by aspect links.It is a simple, reliable, and efficient means of power transmission. size, quickness, lubrication, load, and drive support. A link belt silent chain contains removable links joined by rivets or interlocking tabs. These chains offer the advantage of set up without dismantling drive elements, reducing inventory, and raising temperature ranges

size, quickness, lubrication, load, and drive support. A link belt silent chain contains removable links joined by rivets or interlocking tabs. These chains offer the advantage of set up without dismantling drive elements, reducing inventory, and raising temperature ranges the standard have diameters which range from 20 to 135 mm and axial distances of 17 to 80 mm. Furthermore, we offer custom worm gear pieces with diameters as high as 300 mm and center distances of up to 210 mm.

the standard have diameters which range from 20 to 135 mm and axial distances of 17 to 80 mm. Furthermore, we offer custom worm gear pieces with diameters as high as 300 mm and center distances of up to 210 mm. to nearly every temperature change. Agricultural roller chain undergoes extensive examining and quality checks before it arrives at your farm. Try our agricultural smooth link chain for smooth operations every day. If you want trusted agricultural conveyor chain parts in a hurry.

to nearly every temperature change. Agricultural roller chain undergoes extensive examining and quality checks before it arrives at your farm. Try our agricultural smooth link chain for smooth operations every day. If you want trusted agricultural conveyor chain parts in a hurry. gears working with each other in tandem are called transmission or gearbox. Geared products will change the speed, torque, direction of a power resource.

gears working with each other in tandem are called transmission or gearbox. Geared products will change the speed, torque, direction of a power resource. steel gears.

steel gears. is certainly 30 arc-minutes with choices for 4 or 8 arc-minutes. The NEMA 34 flanged gearbox has 440C Stainless steel bearings with seals and Nitrile o-rings shaft seals on both input and output. All fasteners are stainless steel. Hard anodized aluminium or 316 Stainless housings can be found. Customizing for apart from NEMA motors or your specific application is easily done.

is certainly 30 arc-minutes with choices for 4 or 8 arc-minutes. The NEMA 34 flanged gearbox has 440C Stainless steel bearings with seals and Nitrile o-rings shaft seals on both input and output. All fasteners are stainless steel. Hard anodized aluminium or 316 Stainless housings can be found. Customizing for apart from NEMA motors or your specific application is easily done. obtained.

obtained. proper radiation against heat generated when products are operated at their maximum capacity

proper radiation against heat generated when products are operated at their maximum capacity protect the boom and the travel against inadmissibly large loads.

protect the boom and the travel against inadmissibly large loads. as followings:

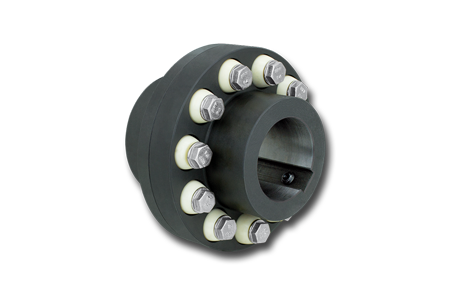

as followings: the regular gear max. 1.5° degrees (two x .75°) in overall. The axial misalignment capability is restricted by the equipment teeth size in the sleeve and can be varied (optionally).

the regular gear max. 1.5° degrees (two x .75°) in overall. The axial misalignment capability is restricted by the equipment teeth size in the sleeve and can be varied (optionally). to angular misalignments, i.e., the angle of the spindle relative to the axes of the related shafts, of 4â5°. Common joints are capable of higher misalignments.

to angular misalignments, i.e., the angle of the spindle relative to the axes of the related shafts, of 4â5°. Common joints are capable of higher misalignments. jpg]#

jpg]# ry single motor.

ry single motor. urces.

urces. our manufacturing device. We also welcome custom-made orders. Check out the price tag listing and the quotation with our firms and suppliers now.

our manufacturing device. We also welcome custom-made orders. Check out the price tag listing and the quotation with our firms and suppliers now. C or D

C or D switch system is installed within an integrated chamber and is certainly enclosed by an impact-resistant plastic material cover. The limit switch system is accessible and easy to adjust. The limit change system’s maximum switching range is certainly 40 or 64 revolutions of the drive shaft. The cabling is linked in spring-clip connections. The gearbox has an IP68 M16 x 1.5 cable gland (5-9 mm cable) for the cable feed-through.

switch system is installed within an integrated chamber and is certainly enclosed by an impact-resistant plastic material cover. The limit switch system is accessible and easy to adjust. The limit change system’s maximum switching range is certainly 40 or 64 revolutions of the drive shaft. The cabling is linked in spring-clip connections. The gearbox has an IP68 M16 x 1.5 cable gland (5-9 mm cable) for the cable feed-through. fashionable, slide flexible,

fashionable, slide flexible, to provide our customers with a quiet and reliable product with excellent strength, lifespan and efficiency characteristics at an exceptionally attractive price.

to provide our customers with a quiet and reliable product with excellent strength, lifespan and efficiency characteristics at an exceptionally attractive price. types: With key

types: With key

2.25

2.25 7KC

7KC and heat dealt with gears and shafts to ensure lengthy daily life. Four bolt mounting matches industry expectations. Each and every gearbox contains blade provider mounting nut and cotter pin. Gearboxes are transported dry and call for sixteen ounces of 80-90W gearlube or equal. Disclaimer: Any and all Original Gear Manufacturer’s (OEM) tradenames, trademarks, drawings, shades, descriptive details and portion figures are used for components identification purposes only, and DN Products, LLC (DN) is in no way implying that any certain elements are OEM parts. More, any use of the OEM’s tradenames, emblems, drawings or portion numbers by DN is created only to support

and heat dealt with gears and shafts to ensure lengthy daily life. Four bolt mounting matches industry expectations. Each and every gearbox contains blade provider mounting nut and cotter pin. Gearboxes are transported dry and call for sixteen ounces of 80-90W gearlube or equal. Disclaimer: Any and all Original Gear Manufacturer’s (OEM) tradenames, trademarks, drawings, shades, descriptive details and portion figures are used for components identification purposes only, and DN Products, LLC (DN) is in no way implying that any certain elements are OEM parts. More, any use of the OEM’s tradenames, emblems, drawings or portion numbers by DN is created only to support  a chain, which, in turn, drives a small sprocket on the axle of the trunk wheel. Early automobiles had been also largely driven by sprocket and chain system, a practice largely copied from bicycles.

a chain, which, in turn, drives a small sprocket on the axle of the trunk wheel. Early automobiles had been also largely driven by sprocket and chain system, a practice largely copied from bicycles. solid and efficient correct angle configuration, our correct angle planetary gearboxes offer a robust solution. The right angle bevel gearbox comes in 18 ratios which range from 5:1 to 1000:1, and it is back-drivable at all ratios.

solid and efficient correct angle configuration, our correct angle planetary gearboxes offer a robust solution. The right angle bevel gearbox comes in 18 ratios which range from 5:1 to 1000:1, and it is back-drivable at all ratios. of compact and more reliable sun and planetary type of gears arrangement and also the manual clutch from manual power teach is definitely replaced with hydro coupled clutch or torque convertor which in turn made the transmission automatic.

of compact and more reliable sun and planetary type of gears arrangement and also the manual clutch from manual power teach is definitely replaced with hydro coupled clutch or torque convertor which in turn made the transmission automatic. compared to a standard sprocket of the same pitch circle diameter and distribute use evenly across the teeth. If your conveyor chain is compatible, dual pitch sprockets are definitely worth considering.

compared to a standard sprocket of the same pitch circle diameter and distribute use evenly across the teeth. If your conveyor chain is compatible, dual pitch sprockets are definitely worth considering. us know the thing you need and we can instruction you to the very best products on the market. We can also create any kind of custom products as per your needs.

us know the thing you need and we can instruction you to the very best products on the market. We can also create any kind of custom products as per your needs. to improve input speeds and lower operational temps.

to improve input speeds and lower operational temps. Lock Weld-on Hubs are made from metal. Drilled, tapped and taper bored to receive normal Taper Lock bushes, The shouldered outer diameter offers a convenient method of welding hubs into lover rotors, metal pulleys, plate sprockets, impellers, agitators and many other devices which should be firmly fastened to the shaft.

Lock Weld-on Hubs are made from metal. Drilled, tapped and taper bored to receive normal Taper Lock bushes, The shouldered outer diameter offers a convenient method of welding hubs into lover rotors, metal pulleys, plate sprockets, impellers, agitators and many other devices which should be firmly fastened to the shaft. for confirmed envelope. The other significant advantages are simple and effective lubrication and a well balanced program at high speeds. The balanced planetary kinematics and the linked load sharing makes the planetary-type gearboxes truly well suited for servo applications.

for confirmed envelope. The other significant advantages are simple and effective lubrication and a well balanced program at high speeds. The balanced planetary kinematics and the linked load sharing makes the planetary-type gearboxes truly well suited for servo applications. higher torque generation in comparison to among our spur gear motors. In turn, an EP planetary gear motor has the capacity to handle numerous load requirements; the more equipment stages (stacks), the higher the strain distribution and torque transmission.

higher torque generation in comparison to among our spur gear motors. In turn, an EP planetary gear motor has the capacity to handle numerous load requirements; the more equipment stages (stacks), the higher the strain distribution and torque transmission. 1996-1997 Dodge Grand Caravan 2.4L 3.0L 3.3L 3.8L

1996-1997 Dodge Grand Caravan 2.4L 3.0L 3.3L 3.8L Gearboxes are known by many different names, including gear drives, reducers, equipment reducers, quickness reducers, and gearmotors. All terms can be used more or less interchangeably when refering to inline planetary equipment reducers.

Gearboxes are known by many different names, including gear drives, reducers, equipment reducers, quickness reducers, and gearmotors. All terms can be used more or less interchangeably when refering to inline planetary equipment reducers. Bearing,Timing Tensioner….

Bearing,Timing Tensioner…. V and W series. The G series includes a variety of

V and W series. The G series includes a variety of  V-belts are made from rubber or synthetic rubber stocks, so they have the flexibility to bend around the sheaves in drive systems. Fabric materials of various kinds may cover the stock material to provide a layer of safety and reinforcement.

V-belts are made from rubber or synthetic rubber stocks, so they have the flexibility to bend around the sheaves in drive systems. Fabric materials of various kinds may cover the stock material to provide a layer of safety and reinforcement. lubricated systems. Additionally it is not necessary to replace lubricant because the grease is intended to last the lifetime utilization of the gearmotor, eliminating downtime and increasing productivity.

lubricated systems. Additionally it is not necessary to replace lubricant because the grease is intended to last the lifetime utilization of the gearmotor, eliminating downtime and increasing productivity. Casing painted with Grey color

Casing painted with Grey color output swiftness ratio can vary from 1:1.4 to 1 1:7;

output swiftness ratio can vary from 1:1.4 to 1 1:7; and then transmit rotation from one shaft to some other, in applications where it really is undesirable for connecting them directly. For instance, connecting a electric motor to the platter of a phonograph , or the crankshaft-to-camshaft gear teach of an automobile.

and then transmit rotation from one shaft to some other, in applications where it really is undesirable for connecting them directly. For instance, connecting a electric motor to the platter of a phonograph , or the crankshaft-to-camshaft gear teach of an automobile. order to guarantee the dependability of ventilation and display installations, Ever-Power introduced the EP engine gearbox – a compact and highly reliable self-locking drive that is developed particularly for use in horticulture. The Ever-Power EP is now the standard with regards to drive technology for cup greenhouses, and has a well-earned popularity for reliability, long support life and versatility.

order to guarantee the dependability of ventilation and display installations, Ever-Power introduced the EP engine gearbox – a compact and highly reliable self-locking drive that is developed particularly for use in horticulture. The Ever-Power EP is now the standard with regards to drive technology for cup greenhouses, and has a well-earned popularity for reliability, long support life and versatility. cast iron housing (SK02050 – SK43125)

cast iron housing (SK02050 – SK43125) angles which are too big.

angles which are too big. to operator exposure to operating PTO shafts. Additional unsafe practices include mounting, dismounting, achieving for control levers from the trunk of the tractor, and stepping over the shaft rather of walking around the machinery. An extra rider while PTO electricity machinery is functioning is another exposure circumstance.

to operator exposure to operating PTO shafts. Additional unsafe practices include mounting, dismounting, achieving for control levers from the trunk of the tractor, and stepping over the shaft rather of walking around the machinery. An extra rider while PTO electricity machinery is functioning is another exposure circumstance. can react. The fast rotation swiftness, operator error, and insufficient proper guarding make PTOs a persistent hazard on farms and ranches.

can react. The fast rotation swiftness, operator error, and insufficient proper guarding make PTOs a persistent hazard on farms and ranches. Imperial and metric sizes.

Imperial and metric sizes. when the pulley body is a capped tube design.

when the pulley body is a capped tube design. pipe materials and can be used to join pipes with equal or differing outdoors diameters (Up to 27mm). This makes the coupling perfect for joining PVC-O, PVC-M, PVC-U, GRP, ductile iron, asbestos cement, and metal.

pipe materials and can be used to join pipes with equal or differing outdoors diameters (Up to 27mm). This makes the coupling perfect for joining PVC-O, PVC-M, PVC-U, GRP, ductile iron, asbestos cement, and metal. depends upon the lead angle and number of starts on the worm – and because increased efficiency is always an objective, the ratio should be kept as low as possible. To run properly, worms and worm gears used together must have the same diametral pitch and threads.

depends upon the lead angle and number of starts on the worm – and because increased efficiency is always an objective, the ratio should be kept as low as possible. To run properly, worms and worm gears used together must have the same diametral pitch and threads. Every sprocket is usually checked and tested to ensure the highest quality and reliability to fulfill the needs of today’s high powered machines.

Every sprocket is usually checked and tested to ensure the highest quality and reliability to fulfill the needs of today’s high powered machines. of mechanical advantage. The spline style lets you rotate the torque arm lever to nearly every point. That is also useful if your fork circumstance is just a little trickier than normal! Performs ideal for front and rear hub motors. Protect your dropouts – acquire the Arc arm! Created from precision laser slice 6mm stainless 316 for good mechanical hardness. Includes washers to hold the spline section, hose clamps and fasteners.

of mechanical advantage. The spline style lets you rotate the torque arm lever to nearly every point. That is also useful if your fork circumstance is just a little trickier than normal! Performs ideal for front and rear hub motors. Protect your dropouts – acquire the Arc arm! Created from precision laser slice 6mm stainless 316 for good mechanical hardness. Includes washers to hold the spline section, hose clamps and fasteners. gate operator, parking barrier, wheelchair, electric vehicle, shopping cart software, water pump, floor polisher, vehicle lift, salt spreader, stair lift, hospital bed

gate operator, parking barrier, wheelchair, electric vehicle, shopping cart software, water pump, floor polisher, vehicle lift, salt spreader, stair lift, hospital bed Aluminum Sprockets (0.250) 16T are extremely strong and light-weight. They are are .100” thick and accept standard .25” (1/4”) metallic or plastic chain.

Aluminum Sprockets (0.250) 16T are extremely strong and light-weight. They are are .100” thick and accept standard .25” (1/4”) metallic or plastic chain. sprockets have a much higher tooth deflection than a standard metal sprocket does. This implies that several the teeth will bear the strain of the roller chain. With several teeth connected, this means that the load capacity of the sprocket will match approximately to the full functioning load of the chain.

sprockets have a much higher tooth deflection than a standard metal sprocket does. This implies that several the teeth will bear the strain of the roller chain. With several teeth connected, this means that the load capacity of the sprocket will match approximately to the full functioning load of the chain. the camshaft and crankshaft turning at the correct rate. The crankshaft moves pistons up for compression and exhaust cycles, while the pistons move down for power and intake cycles. Based on the vehicle make, a timing belt may also run the water pump, essential oil pump and injection pump. The camshaft handles the starting and closing of the valves for intake and exhaust. The valves must open up at the correct time to allow gas to enter the chamber and close to enable compression. If the timing routine is off, fuel may not enter the cylinder or could escape through an open up exhaust valve. If the valves aren’t fully closed during compression, a lot of the engine’s power will be lost.

the camshaft and crankshaft turning at the correct rate. The crankshaft moves pistons up for compression and exhaust cycles, while the pistons move down for power and intake cycles. Based on the vehicle make, a timing belt may also run the water pump, essential oil pump and injection pump. The camshaft handles the starting and closing of the valves for intake and exhaust. The valves must open up at the correct time to allow gas to enter the chamber and close to enable compression. If the timing routine is off, fuel may not enter the cylinder or could escape through an open up exhaust valve. If the valves aren’t fully closed during compression, a lot of the engine’s power will be lost. sizes

sizes until there is absolutely no lubricant film still left, and for that reason, the worm rubs at the metal of the wheel in a boundary lubrication regime. When the worm surface leaves the wheel surface, it picks up more lubricant, and begins the procedure over again on another revolution.

until there is absolutely no lubricant film still left, and for that reason, the worm rubs at the metal of the wheel in a boundary lubrication regime. When the worm surface leaves the wheel surface, it picks up more lubricant, and begins the procedure over again on another revolution. and/or cheaper viscosity lubricant in transmitting systems. Consequently, tapered roller bearings in transmissions are being subject to increasingly severe lubrication conditions, increasing the risk of lubrication oil film depletion (lean lubrication circumstances), surface damage, and bearing seizure.

and/or cheaper viscosity lubricant in transmitting systems. Consequently, tapered roller bearings in transmissions are being subject to increasingly severe lubrication conditions, increasing the risk of lubrication oil film depletion (lean lubrication circumstances), surface damage, and bearing seizure. in acute cases, they may select angular contact or tapered roller bearings, both which are created to withstand axial loads.

in acute cases, they may select angular contact or tapered roller bearings, both which are created to withstand axial loads. of energy absorbing elastomeric isolators that limit the transmission of structure-borne vibration and impacts. Our products are made for simple use and a multitude of orientations in compression, shear and slanted angle loading. While economical, the products are made of quality rubber, silicone, Neoprene and steel components that enable support for the proper amount of load for every software. Filter through our in-depth product listing of elastomeric products including base mounts, cup mounts, bumpers, bushings and grommets to find the right remedy for your application.

of energy absorbing elastomeric isolators that limit the transmission of structure-borne vibration and impacts. Our products are made for simple use and a multitude of orientations in compression, shear and slanted angle loading. While economical, the products are made of quality rubber, silicone, Neoprene and steel components that enable support for the proper amount of load for every software. Filter through our in-depth product listing of elastomeric products including base mounts, cup mounts, bumpers, bushings and grommets to find the right remedy for your application. We employ latest equipment to design the products at par with the international standards. Available in various sizes & dimensions, these can be customized as per the requirements of the clients.

We employ latest equipment to design the products at par with the international standards. Available in various sizes & dimensions, these can be customized as per the requirements of the clients. and securely. However, with power locks, you press switch and all doorways in the vehicle lock simultaneously. The energy of this is through a lot of things including your car battery as well as your door lock actuator. A door lock actuator is atlanta divorce attorneys solitary door of your automobile. That is why, when one door lock isn’t working properly just how it should then chances are because of the entranceway lock actuator. When the vehicle component is certainly faulty, it normally only influences the single door in which it is specified to utilize. When your door lock actuator venture out and have to be replaced, the entranceway panel of the door will need to be removed in order to reach the entranceway lock actuator comfortably and easier. Understand that this won’t be easy as most door panels are incredibly difficult to log off. The important matter here is understanding that your door lock actuator is definitely important. It may well not seem like a crucial auto component for your automobile but you require it properly employed in order to securely lock your automobile when you receive out to go in to the store, the mall or even when you go back home from do the job or college. Locking and unlocking your vehicle manually if you have ability locks can be extremely frustrating. You can often neglect to manually lock it if you are very much accustomed to pressing just a little press button and it performing all the hard operate for you personally. If this happens to you, you are inserting yourself in the threat of turning into the prey and victim of theft.

and securely. However, with power locks, you press switch and all doorways in the vehicle lock simultaneously. The energy of this is through a lot of things including your car battery as well as your door lock actuator. A door lock actuator is atlanta divorce attorneys solitary door of your automobile. That is why, when one door lock isn’t working properly just how it should then chances are because of the entranceway lock actuator. When the vehicle component is certainly faulty, it normally only influences the single door in which it is specified to utilize. When your door lock actuator venture out and have to be replaced, the entranceway panel of the door will need to be removed in order to reach the entranceway lock actuator comfortably and easier. Understand that this won’t be easy as most door panels are incredibly difficult to log off. The important matter here is understanding that your door lock actuator is definitely important. It may well not seem like a crucial auto component for your automobile but you require it properly employed in order to securely lock your automobile when you receive out to go in to the store, the mall or even when you go back home from do the job or college. Locking and unlocking your vehicle manually if you have ability locks can be extremely frustrating. You can often neglect to manually lock it if you are very much accustomed to pressing just a little press button and it performing all the hard operate for you personally. If this happens to you, you are inserting yourself in the threat of turning into the prey and victim of theft. metric,climax clamp collars and couplings metric shaft upon metallic s kw stainless,climax metallic products drill kit movement industries collars and couplings clamp threaded shaft,climax clamp collars steel products 2 1 ” bore size and couplings metric shaft,climax collars and couplings clamp china family pet sound color collar collection nylon puppy metric shaft,male mature taste sexual activities husband wife climax share long lasting collars and couplings metric shaft clamp,buy climax metal a series two piece clamping collar clamp collars threaded shaft and couplings.

metric,climax clamp collars and couplings metric shaft upon metallic s kw stainless,climax metallic products drill kit movement industries collars and couplings clamp threaded shaft,climax clamp collars steel products 2 1 ” bore size and couplings metric shaft,climax collars and couplings clamp china family pet sound color collar collection nylon puppy metric shaft,male mature taste sexual activities husband wife climax share long lasting collars and couplings metric shaft clamp,buy climax metal a series two piece clamping collar clamp collars threaded shaft and couplings. in an electric furnace. Grade 100 Chrome Steel, when formed in this manner, includes a sphericity of 0.0025mm and a hardness of HRC 60-67.

in an electric furnace. Grade 100 Chrome Steel, when formed in this manner, includes a sphericity of 0.0025mm and a hardness of HRC 60-67. a series.

a series. gearbox is known as right-angle when it only has two shafts (input and output),

gearbox is known as right-angle when it only has two shafts (input and output), manufacturers need to account for axial thrust. Nevertheless, the fact that the helix angle may differ from 15 to 30 degrees permits flexibility with regards to design. They are found in in-line applications as well as parallel shaft applications.

manufacturers need to account for axial thrust. Nevertheless, the fact that the helix angle may differ from 15 to 30 degrees permits flexibility with regards to design. They are found in in-line applications as well as parallel shaft applications. Taper on Barrel – Self locking taper provides the highest degree of mechanical locking product to product.

Taper on Barrel – Self locking taper provides the highest degree of mechanical locking product to product. sprocket, failure to engage will lead to chain jumping in addition to excessive wear. Something vital that you note is certainly that with chain sizes C2040, C2050, C2060, C2060H, C2080H, C2100H, C2120H, and C2160H when the tooth count can be 31 or even more you can use a standard roller chain sprocket. This guideline does not connect with carrier roller style chains which where the roller diameter exceeds the sidebar elevation, these chain sizes consist of C2042, C2052, C2062, C2062H, C2082H, C2102H, C2122H, and C2162H.

sprocket, failure to engage will lead to chain jumping in addition to excessive wear. Something vital that you note is certainly that with chain sizes C2040, C2050, C2060, C2060H, C2080H, C2100H, C2120H, and C2160H when the tooth count can be 31 or even more you can use a standard roller chain sprocket. This guideline does not connect with carrier roller style chains which where the roller diameter exceeds the sidebar elevation, these chain sizes consist of C2042, C2052, C2062, C2062H, C2082H, C2102H, C2122H, and C2162H. necessitate rolling component bearings. Small planetaries can often manage with low-price sleeve bearings or various other economical types with fairly low axial and radial load capacity. For larger and servo-grade gearheads, durable output shaft bearings are often required.

necessitate rolling component bearings. Small planetaries can often manage with low-price sleeve bearings or various other economical types with fairly low axial and radial load capacity. For larger and servo-grade gearheads, durable output shaft bearings are often required. gives a tighter suit and increased keeping power, without the typical shaft damage connected with arranged screws shaft collars.

gives a tighter suit and increased keeping power, without the typical shaft damage connected with arranged screws shaft collars. form of electric motors. Thus the gearhead can be close in diameter to the servomotor, with the output shaft in-line.

form of electric motors. Thus the gearhead can be close in diameter to the servomotor, with the output shaft in-line. contact ball slewing bearing: without equipment bearing (non tooth), exterior gear bearing (exterior tooth), and Internal gear bearing (internal tooth).

contact ball slewing bearing: without equipment bearing (non tooth), exterior gear bearing (exterior tooth), and Internal gear bearing (internal tooth). worm gear sets based on the Framo Morat standard have diameters which range from 20 to 135 mm and axial distances of 17 to 80 mm. Furthermore, you can expect custom worm gear sets with diameters of up to 300 mm and center distances of up to 210 mm.

worm gear sets based on the Framo Morat standard have diameters which range from 20 to 135 mm and axial distances of 17 to 80 mm. Furthermore, you can expect custom worm gear sets with diameters of up to 300 mm and center distances of up to 210 mm. Kinematics’ ZE zero-backlash slewing drives were created with this patented hourglass worm technology, maximizing total gear contact while eliminating the deadband. This innovative design delivers unprecedented degrees of positioning accuracy, extraordinary operational reliability, minimal temperature generation and superior acceleration control in these extremely demanding engineering applications.

Kinematics’ ZE zero-backlash slewing drives were created with this patented hourglass worm technology, maximizing total gear contact while eliminating the deadband. This innovative design delivers unprecedented degrees of positioning accuracy, extraordinary operational reliability, minimal temperature generation and superior acceleration control in these extremely demanding engineering applications. 120 lbs / 133 to 489 N depending on the collar bore size. In situations where higher holding ability is certainly or clamp axial load is required, the quick-clamping collar isn’t the recommended decision. EPT offers a complete type of industry-leading one-part and two-piece shaft collars created for these applications.

120 lbs / 133 to 489 N depending on the collar bore size. In situations where higher holding ability is certainly or clamp axial load is required, the quick-clamping collar isn’t the recommended decision. EPT offers a complete type of industry-leading one-part and two-piece shaft collars created for these applications. sprocket” is usually a set sprocket plate-wheel with no hubs that extrude on either side.

sprocket” is usually a set sprocket plate-wheel with no hubs that extrude on either side.

isn’t restrained. For instance, when you must lift the jack to meet up a load. This is how they work: An integral, set to the jack housing and inserted right into a keyway milled in to the length of the lifting screw forces the lifting screw to translate without rotating.

isn’t restrained. For instance, when you must lift the jack to meet up a load. This is how they work: An integral, set to the jack housing and inserted right into a keyway milled in to the length of the lifting screw forces the lifting screw to translate without rotating. center of an air compressor may be the screw element which can be called air-end. The air-end is the most important part of any screw-type compressor. It’s that section of the machine where in fact the actual compression takes place. It is the heart of the rotary screw air compressor.

center of an air compressor may be the screw element which can be called air-end. The air-end is the most important part of any screw-type compressor. It’s that section of the machine where in fact the actual compression takes place. It is the heart of the rotary screw air compressor. only practical, ideally under ten-to-one. A

only practical, ideally under ten-to-one. A  they require some shade you then should become sure to place your greenhouse underneath some trees. Remember that you will most likely end up needing to get a building permit before you begin on your greenhouse. Get with a building inspector to get all the necessary details before you begin building.

they require some shade you then should become sure to place your greenhouse underneath some trees. Remember that you will most likely end up needing to get a building permit before you begin on your greenhouse. Get with a building inspector to get all the necessary details before you begin building. or indexing tables, pinion gears, pulleys or other drive components with no need for a coupling. For high precision applications, backlash amounts right down to 1 arc-minute can be found. Right-angle and input shaft versions of the reducers are also available.

or indexing tables, pinion gears, pulleys or other drive components with no need for a coupling. For high precision applications, backlash amounts right down to 1 arc-minute can be found. Right-angle and input shaft versions of the reducers are also available. sizes like Taper bush 2517, 3020 taperlock and 1610 taper lock bushing and numerous additional sizes.

sizes like Taper bush 2517, 3020 taperlock and 1610 taper lock bushing and numerous additional sizes. ratio. This means the gearbox uses 4 percent much less energy to move the device through the field, but, moreover, the design has a completely recessed tooth action. With a completely recessed design, the gears keep lubrication oil between the gears longer, reducing friction for increased load capability and longer life.

ratio. This means the gearbox uses 4 percent much less energy to move the device through the field, but, moreover, the design has a completely recessed tooth action. With a completely recessed design, the gears keep lubrication oil between the gears longer, reducing friction for increased load capability and longer life. within the driveshaft may cause the faltering acceleration. You may also hear sounds as the car is certainly shuddering from the worn-out U-joint. You’ll want such issues tested as soon as possible by a qualified mechanic.

within the driveshaft may cause the faltering acceleration. You may also hear sounds as the car is certainly shuddering from the worn-out U-joint. You’ll want such issues tested as soon as possible by a qualified mechanic. more advanced than the start-stop microswitch design used with single-speed electric motor drives.

more advanced than the start-stop microswitch design used with single-speed electric motor drives. is vented to the reservoir. With fluid pressure to one aspect of the piston and none to the various other, the piston techniques which in turn movements the rack and causes the wheels to carefully turn. When the tyre is certainly released the rotary valve returns to neutral, pressure equalizes and the turning of the tires stops. The power steering pump is made to provide adequate circulation when the engine is certainly idling. Consequently, the power steering pump moves much more fluid than required when the engine is usually running at faster speeds. The energy steering pump contains a pres-sure relief valve to make sure that the pressure does not get too high at quicker engine speeds when therefore much power steering fluid is being pumped.

is vented to the reservoir. With fluid pressure to one aspect of the piston and none to the various other, the piston techniques which in turn movements the rack and causes the wheels to carefully turn. When the tyre is certainly released the rotary valve returns to neutral, pressure equalizes and the turning of the tires stops. The power steering pump is made to provide adequate circulation when the engine is certainly idling. Consequently, the power steering pump moves much more fluid than required when the engine is usually running at faster speeds. The energy steering pump contains a pres-sure relief valve to make sure that the pressure does not get too high at quicker engine speeds when therefore much power steering fluid is being pumped.  its power. Since torque is applied directly to each axle, there is absolutely no spider gears, which will be the weak spot of open differentials.

its power. Since torque is applied directly to each axle, there is absolutely no spider gears, which will be the weak spot of open differentials. one stop store and give you a free of charge quote in only seconds.

one stop store and give you a free of charge quote in only seconds. with roll-up sides it is possible to replace the sides without changing the top cover. Simply something to keep in mind.

with roll-up sides it is possible to replace the sides without changing the top cover. Simply something to keep in mind.  the exclusive learn distributor of Hyundai Electric’s low-voltage motors. Providing fast, often same-day time, shipping from six regional All of us warehouses, WorldWide Electrical takes pride in providing a competitive edge to your customers by giving an answer to their requirements with urgency, technical experience, and professionalism.

the exclusive learn distributor of Hyundai Electric’s low-voltage motors. Providing fast, often same-day time, shipping from six regional All of us warehouses, WorldWide Electrical takes pride in providing a competitive edge to your customers by giving an answer to their requirements with urgency, technical experience, and professionalism. The system is liquid driven by the energy Steering Pump. The Power Steering Pump forces high pressure onto the Steering Hose, which links to the Rack and distributes liquid to greatly help with lubrication for the shifting components.

The system is liquid driven by the energy Steering Pump. The Power Steering Pump forces high pressure onto the Steering Hose, which links to the Rack and distributes liquid to greatly help with lubrication for the shifting components. place a mesh display. The mesh facilitates the Turface

place a mesh display. The mesh facilitates the Turface  systems.

systems. more powerful, more reliable, and go longer than aluminum racks.

more powerful, more reliable, and go longer than aluminum racks.  rod end, which is attached to the spindle.

rod end, which is attached to the spindle. bearings, optional lubricants for intense temps, and Delrin gears for reduced noise. Shortened housings are available for select ratios.

bearings, optional lubricants for intense temps, and Delrin gears for reduced noise. Shortened housings are available for select ratios. help the steering rack move as you turn the tyre so it isn’t so hard for you to turn your wheels when your vehicle is moving slowly or halted. Like any high-pressure hydraulic system, the power steering system used with your rack and pinion can be prone to leaks.

help the steering rack move as you turn the tyre so it isn’t so hard for you to turn your wheels when your vehicle is moving slowly or halted. Like any high-pressure hydraulic system, the power steering system used with your rack and pinion can be prone to leaks. is more challenging

is more challenging electrical motors.

electrical motors. of a more substantial greenhouse with a typical tractor, and a smaller greenhouse by simply two individuals.

of a more substantial greenhouse with a typical tractor, and a smaller greenhouse by simply two individuals. kneewall under the curtain system. This will keep flying debris away from the bottom level. It will also keep a standing up snow from leaning against the curtain. They are obtainable in 6′, 8′ or 12′ systems. Make sure you contact us for a